Top 10 Process Machinery Types You Should Know for Your Business

In today's competitive landscape, understanding the nuances of process machinery is vital for businesses aiming to enhance productivity and efficiency. According to a recent report by the International Society of Automation (ISA), the global process machinery market is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2028. This surge is attributed to the increasing demand for automation and the modernization of manufacturing facilities. Experts highlight the role of advanced technologies in driving this growth, underscoring the need for companies to adapt to evolving industry standards in order to maintain a competitive edge.

Industry expert Dr. Margaret Lin, a renowned authority in process engineering, emphasizes, "Understanding the core types of process machinery is not just beneficial; it is imperative for operational success." With the integration of AI and IoT within process machinery, businesses can significantly optimize their processes, reducing downtime and boosting output. Familiarity with the ten essential types of process machinery can empower companies to make informed decisions, streamline operations, and ultimately enhance their bottom line. As industries become increasingly reliant on sophisticated machinery, this knowledge becomes an indispensable asset for any forward-thinking organization.

Overview of Process Machinery and Its Importance in Business

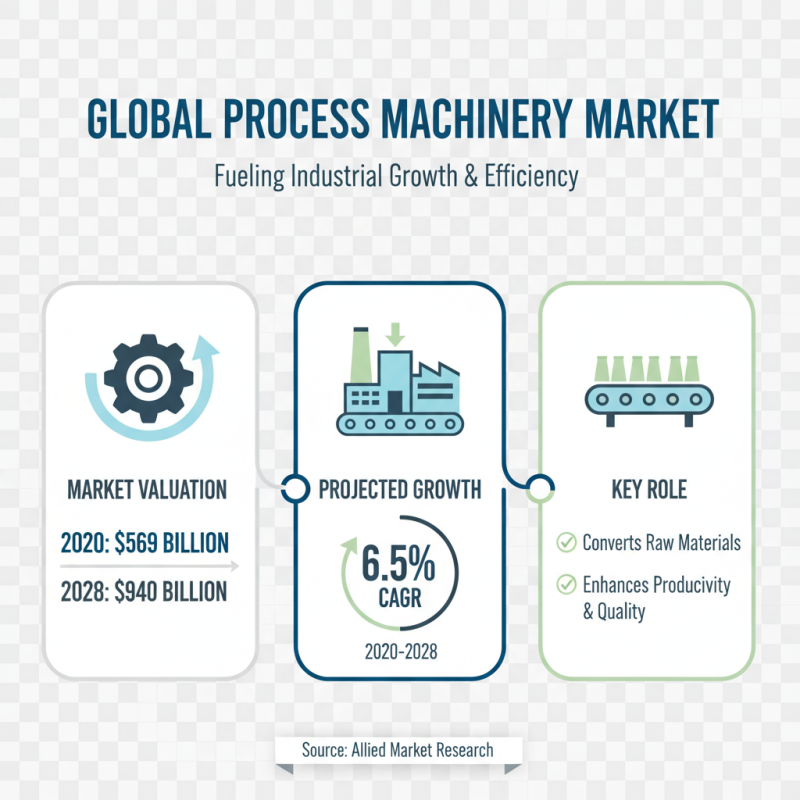

Process machinery plays a crucial role in various industries, serving as the backbone for efficient production and operational workflows. This equipment is designed to convert raw materials into finished goods, which is vital for maintaining quality and consistency in manufacturing processes. According to a report by Allied Market Research, the global process machinery market was valued at approximately $569 billion in 2020 and is projected to reach $940 billion by 2028, growing at a compound annual growth rate (CAGR) of around 6.5%. This growth underscores the significance of process machinery in boosting productivity and enhancing the overall competitiveness of businesses.

The importance of process machinery in business cannot be overstated, as it directly impacts operational efficiency and cost management. By investing in advanced machinery, businesses can reduce production times, lower waste, and improve product quality. A study conducted by McKinsey & Company highlights that companies implementing automation in their machinery operations can see productivity increases of 20-30%, significantly influencing their bottom line. Industries ranging from food and beverage to pharmaceuticals rely heavily on process machinery to ensure compliance with safety standards while also meeting consumer demand effectively. As technology progresses, embracing modern process machinery becomes imperative for businesses looking to thrive in an increasingly competitive landscape.

Key Types of Process Machinery Commonly Used in Various Industries

Process machinery plays a crucial role in various industries, enabling the efficient transformation of raw materials into finished products. Understanding the types of process machinery is essential for optimizing production and maintaining competitive advantages in today's market. The most common types of process machinery include mixers, conveyors, crushers, and heat exchangers. For instance, according to the International Federation of Robotics, the global market for conveyors is projected to reach $8.4 billion by 2025, driven by advancements in automation technology.

In industries ranging from food and beverage to pharmaceuticals, mixers are vital for ensuring homogeneity in product formulations. The size of the global industrial mixing market is expected to grow to $6 billion by 2027, highlighting the increasing reliance on advanced mixing solutions. Crushers, which are essential in materials processing, also hold significant importance; the global crushing equipment market is anticipated to reach $4.6 billion by 2025. Concurrently, heat exchangers are indispensable in energy-intensive industries, as they improve energy efficiency and reduce operational costs, with the global market for heat exchangers projected to exceed $20 billion by 2026.

These statistics underscore the significance of investing in the right process machinery to enhance operational efficiency and product quality in any business. As industrial sectors continue to evolve, staying informed about the latest machinery types will enable companies to leverage their capabilities effectively.

Detailed Analysis of Each Type: Functionality and Applications

Understanding the functionality and applications of various process machinery types is essential for businesses aiming to optimize productivity and efficiency. For instance, pumps are a critical component in many industries, facilitating the movement of liquids and slurries. According to a recent report by MarketsandMarkets, the global pump market is projected to reach USD 79.2 billion by 2026, driven by increased demand in water treatment and manufacturing sectors.

Additionally, mixers play a vital role in blending materials uniformly, and their application spans pharmaceuticals to food processing. The versatile nature of mixers allows for customization based on the viscosity and thermal properties of substances being mixed.

Another important type of machinery includes conveyors, essential for automating material handling. Reports predict the global conveyor system market will grow significantly, as businesses seek to enhance operational efficiency.

With the ability to transport products over long distances and complex layouts, conveyors reduce manual labor and improve speed, especially in logistics and packaging. Similarly, compressors are crucial in various applications, from refrigeration to pneumatic systems, with a projected CAGR of 3.8% from 2023 to 2028 as companies invest in energy-efficient solutions.

Tips: When considering machinery for your business, prioritize equipment that aligns with your specific operational needs and scalability potential. Conducting a thorough needs assessment and consulting with industry experts can lead to better investment decisions. Additionally, regularly evaluating the performance and efficiency of your process machinery can help identify areas for improvement and increase overall profitability.

Factors to Consider When Selecting Process Machinery for Your Business

When selecting process machinery for your business, several key factors must be taken into consideration to ensure optimal efficiency and productivity. First and foremost, the compatibility of machinery with existing systems is crucial. According to a recent industry report by the International Society for Automation, 75% of manufacturing failures can be attributed to inadequate integration between new and existing equipment. Ensuring that the process machinery can seamlessly connect with current technology will minimize downtime and enhance workflow.

Another critical element to consider is the scalability of the machinery. As businesses strive for growth, having versatile equipment that can adapt to increased production demands is essential. In fact, a study by MarketsandMarkets predicts that the global market for process machinery will grow from $40 billion in 2022 to over $60 billion by 2027, highlighting the need for businesses to invest in flexible solutions that can accommodate future expansions. Furthermore, the reliability and maintenance requirements of the machinery should not be overlooked; companies that prioritize these aspects can expect a 20% reduction in operational costs, as indicated by research from the Manufacturing Institute.

Finally, it's vital to assess the energy efficiency of the process machinery. With energy costs on the rise, selecting equipment that adheres to sustainability standards can significantly impact your bottom line. A report by the U.S. Department of Energy emphasizes that energy-efficient machinery can lower operational expenses by up to 30%, offering substantial savings over time. Thus, aligning machinery selection with both operational needs and long-term sustainability goals will empower businesses to thrive in an increasingly competitive market.

Top 10 Process Machinery Types You Should Know for Your Business

| Machinery Type | Description | Industry Applications | Key Factors to Consider |

|---|---|---|---|

| Pumps | Devices to move fluids through hydraulic systems. | Chemical, Oil & Gas, Water Treatment | Flow rate, Material compatibility, Energy efficiency |

| Compressors | Machines that increase the pressure of gases. | Manufacturing, HVAC, Refrigeration | Efficiency, Maintenance requirements, Noise levels |

| Mixers | Equipment for combining materials to achieve desired consistency. | Food, Pharmaceuticals, Chemicals | Speed control, Capacity, Cleanability |

| Conveyors | Mechanisms for transporting materials from one location to another. | Manufacturing, Mining, Packaging | Load capacity, Speed, Space requirements |

| Heat Exchangers | Devices that transfer heat between two or more fluids. | Power Generation, Petrochemical, HVAC | Thermal efficiency, Size, Maintenance |

| Separators | Equipment that separates materials based on physical properties. | Food, Waste Treatment, Mining | Separation efficiency, Feed rate, Energy consumption |

| Furnaces | Heating equipment used for melting or processing materials. | Metallurgy, Ceramics, Glass | Temperature control, Material durability, Fuel type |

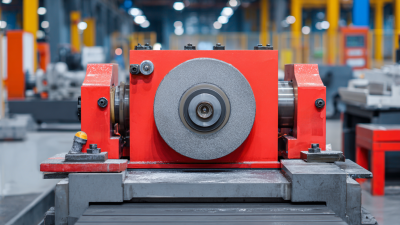

| Grinding Machines | Machines used to grind materials to a desired particle size. | Mining, Construction, Food | Feed size, Grinding efficiency, Maintenance |

| Packaging Machines | Equipment that packages products for sale and distribution. | Consumer Goods, Pharmaceuticals, Food | Speed, Type of packaging, Automation level |

Maintenance and Efficiency Tips for Process Machinery Usage

When it comes to process machinery, maintaining efficiency is key to ensuring smooth operations and minimizing downtime. One crucial tip for maintaining process machinery is to establish a regular preventive maintenance schedule. This involves routine inspections and servicing to identify and correct potential issues before they become serious problems. Regular upkeep not only prolongs the lifespan of the equipment but also enhances its performance, ensuring that it operates at optimal capacity.

Another vital aspect of efficient machinery usage is proper operator training. Well-trained staff are more adept at recognizing operational anomalies and maintaining equipment correctly, which can significantly reduce the likelihood of malfunctions. Providing ongoing education and training helps keep employees informed about the latest best practices and technological advancements. Additionally, maintaining a clean work environment is essential. Dust and debris can adversely affect machinery performance; thus, regular cleaning routines can help sustain efficiency and prevent unnecessary wear and tear on the equipment. By focusing on maintenance and operator competency, businesses can achieve better overall productivity and reduce costs associated with equipment failure.

Related Posts

-

What is Manufacturing Machines and How They Revolutionize Production

-

Top 10 Essential Manufacturing Machines Revolutionizing Production Efficiency

-

Why Automation Machines Are Essential for Modern Manufacturing Success

-

How to Succeed in Industrial Engineering Careers and Master Key Skills

-

Unlocking the Potential of Vibratory Polishing Machines: Tips for Optimal Performance and Maintenance

-

Why You Should Choose Dalal Vibro Finishing Machine for Superior Surface Finishing