Top 10 Manufacturing Machines You Need to Know for Your Business Growth

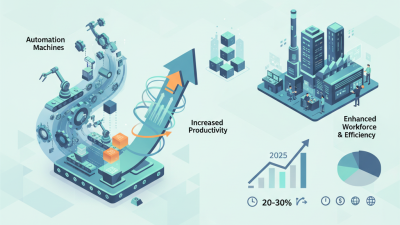

In today's competitive landscape, understanding the pivotal role of manufacturing machines is essential for business growth. The manufacturing sector has been a cornerstone of economic development, contributing to approximately 16% of the global GDP, as reported by the World Bank. As industries evolve, the integration of advanced manufacturing technologies has become increasingly vital. According to a report by McKinsey, companies that adopt automation and smart manufacturing technologies can enhance their productivity by up to 30%, providing a significant edge over competitors.

To navigate this rapidly changing environment, businesses must recognize the top manufacturing machines that can streamline operations, reduce costs, and improve product quality. The rise of Industry 4.0 has further emphasized the importance of investing in innovative machinery that incorporates IoT and artificial intelligence. A study from Deloitte highlights that organizations investing in advanced manufacturing technologies are 7 times more likely to experience substantial growth in revenue and profitability. As such, equipping your business with the right manufacturing machines is not merely an operational necessity but a strategic imperative for long-term success.

Essential Manufacturing Machines for Small and Medium Businesses

In today's competitive landscape, small and medium businesses (SMBs) must leverage essential manufacturing machines to enhance efficiency and drive growth. According to a recent industry analysis conducted by the National Association of Manufacturers, nearly 70% of SMBs are adopting advanced manufacturing technologies to streamline operations and reduce costs. Machines such as CNC machines, 3D printers, and automated assembly lines stand out as key investments that can significantly boost operational productivity.

One critical tip for SMBs is to assess the specific needs of their production processes before investing in manufacturing machines. Understanding the scale of production and the complexity of products will guide businesses in selecting the right equipment for optimal performance. Additionally, integrating machines that are compatible with smart manufacturing systems can facilitate a smoother transition into Industry 4.0, as highlighted in a report by Deloitte, which found that companies embracing digital transformation in manufacturing can experience productivity increases of up to 30%.

Another important consideration is maintenance and training. Regular maintenance of machinery ensures longevity and consistent performance, while training staff on new equipment fosters a culture of efficiency and innovation. A study by the Manufacturing Institute reveals that companies that prioritize employee training report 20% higher performance levels. By investing strategically in manufacturing machines and employee development, SMBs can position themselves for sustained growth and competitiveness in the market.

Key Features of CNC Machining for Modern Manufacturing Solutions

CNC machining has become an indispensable aspect of modern manufacturing, offering unparalleled precision and flexibility. The key features of CNC (Computer Numerical Control) machining enable manufacturers to produce complex parts with minimal human intervention. This technology uses computer programs to control the movements of machinery, resulting in high accuracy and repeatability. Components can be designed using advanced software, which can then be directly translated into machine commands, eliminating errors associated with manual processes.

Tips: When implementing CNC machining in your operations, focus on employee training to ensure effective use of the technology. Regular maintenance of machinery can also enhance performance and extend the lifespan of your equipment.

Another pivotal feature of CNC machining is its ability to work with a variety of materials, ranging from metals to plastics and composites. This versatility allows manufacturers to adjust their production lines to meet changing market demands swiftly. Furthermore, CNC machines can automate repetitive tasks, significantly increasing productivity while reducing labor costs.

Tips: Consider integrating CAD (Computer-Aided Design) software into your workflow for a seamless transition from design to production. Keeping your designs simple yet functional can also optimize machine efficiency and reduce lead times.

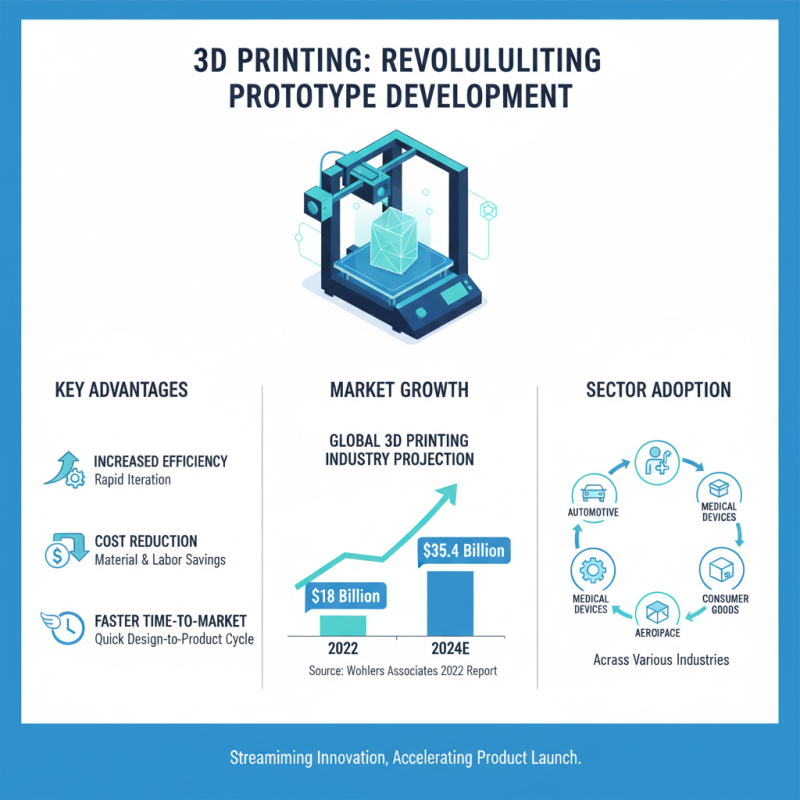

The Importance of 3D Printers in Prototype Development

The significance of 3D printers in prototype development has become increasingly apparent in the manufacturing sector, as businesses strive to enhance efficiency and reduce costs. According to a 2022 report by the Wohlers Associates, the global 3D printing industry is projected to grow to $35.4 billion by 2024, highlighting the technology's rising adoption across various sectors. This rapid expansion showcases how 3D printing can streamline the prototyping process, allowing companies to quickly iterate on designs and bring products to market faster.

One of the key advantages of 3D printing in prototype development is its ability to produce complex geometries that traditional manufacturing methods may struggle to achieve. Research indicates that 90% of manufacturers using 3D printing have reported a decrease in prototype lead times, showcasing a significant improvement over conventional techniques. This can drastically reduce time-to-market and lower costs associated with production tooling and material waste, making it an indispensable tool for businesses looking to foster innovation and maintain a competitive edge in today’s fast-paced market. The strategic integration of 3D printing into prototyping processes not only enhances design capabilities but also empowers manufacturers to respond more agilely to market demands.

How Automation Equipment Enhances Production Efficiency

Automation equipment plays a crucial role in enhancing production efficiency across various manufacturing sectors. By integrating advanced technologies such as robotics, artificial intelligence, and IoT, businesses can streamline their operations and significantly reduce the time taken for production processes. Automation minimizes human error and variability, leading to a consistent output quality that meets customer demands. As a result, companies can optimize their resources and improve overall productivity while reducing operating costs.

Furthermore, automation equipment allows manufacturers to operate with greater flexibility and scalability. With the ability to quickly adjust production lines to accommodate changes in demand or product specifications, businesses can respond swiftly to market trends. This adaptability not only facilitates innovation but also helps in maintaining a competitive edge. As manufacturing evolves, embracing automation becomes imperative for businesses aiming for sustainable growth and superior performance in their respective industries.

Top 10 Manufacturing Machines You Need to Know for Your Business Growth

| Machine Type | Function | Key Features | Efficiency Improvement (%) | Average Cost (USD) |

|---|---|---|---|---|

| CNC Machining Center | Precision Cutting and Shaping | High Speed, Multi-Axis Capability | 25% | 80,000 |

| 3D Printer | Rapid Prototyping | Additive Manufacturing, Versatile Materials | 50% | 20,000 |

| Robotic Arm | Automated Assembly | Programmable, High Precision | 40% | 50,000 |

| Laser Cutting Machine | Material Cutting | High Accuracy, Minimal Waste | 35% | 70,000 |

| Injection Molding Machine | Mass Production of Plastic Parts | Fast Cycle Times, High Volume | 45% | 120,000 |

| Automated Conveyor Systems | Material Handling | Reliable Transport, Modular Design | 30% | 15,000 |

| Industrial Sewing Machine | Textile Manufacturing | Fast Stitching, Adjustable Settings | 20% | 5,000 |

| Press Brake | Metal Forming | Precision Bending, Customizable | 32% | 60,000 |

| Waterjet Cutting Machine | Versatile Material Cutting | No Heat Affected Zone, Complex Shapes | 38% | 90,000 |

| Vertical Milling Machine | Material Removal | Versatile Operations, User-Friendly | 22% | 25,000 |

Understanding the Role of Quality Control Machines in Manufacturing

In the realm of manufacturing, quality control machines play a pivotal role in ensuring that products meet stringent standards and customer expectations. These machines are essential for monitoring and verifying the quality of raw materials and finished goods throughout the production process. By implementing advanced quality control systems, businesses can detect defects early, minimizing waste and reducing rework costs. This proactive approach not only enhances product reliability but also fosters customer trust and loyalty.

Furthermore, the integration of automated quality control machines helps streamline operations, allowing manufacturers to achieve higher efficiency. With real-time data analysis and feedback loops, these machines enable organizations to quickly identify potential issues and make necessary adjustments. As technology continues to evolve, investing in sophisticated quality control solutions can lead to significant improvements in production outcomes. Ultimately, understanding the role of quality control machines is crucial for any business aiming to grow sustainably in a competitive market.

Related Posts

-

Top 10 Essential Manufacturing Machines Revolutionizing Production Efficiency

-

What is Manufacturing Machines and How They Revolutionize Production

-

Top 10 Process Machinery Types You Should Know for Your Business

-

Top 10 Vibratory Polishing Machines for Perfect Finishing

-

Why You Should Choose Dalal Vibro Finishing Machine for Superior Surface Finishing

-

How to Use Automation Machines to Enhance Productivity in 2025