Top 10 Process Machinery Trends Transforming Your Industry in 2023

As we advance into 2023, the process machinery sector is undergoing transformative changes driven by technological innovations and shifting market demands. The integration of cutting-edge technologies such as automation, artificial intelligence, and IoT is reshaping how industries operate, enhancing efficiency and productivity. Companies are increasingly focusing on sustainability and energy efficiency, prompting a re-evaluation of traditional machinery operations.

In this dynamic landscape, understanding the top trends in process machinery is crucial for businesses aiming to remain competitive. By embracing these developments, organizations can optimize their processes, reduce operational costs, and improve overall output quality. This article seeks to highlight the ten key trends that are revolutionizing the process machinery industry, providing valuable insights for professionals looking to navigate this evolving environment and leverage opportunities for growth and innovation.

Emerging Technologies Revolutionizing Process Machinery in 2023

In 2023, the process machinery industry is witnessing significant transformations driven by emerging technologies. Data from the International Federation of Robotics indicates that worldwide sales of industrial robots have surged by 30% compared to the previous year, highlighting the integration of automation in manufacturing processes. This shift not only enhances operational efficiency but also reduces the likelihood of human errors, thereby elevating safety standards across the board.

Moreover, the rise of the Internet of Things (IoT) is fundamentally altering the landscape of process machinery. According to a report by MarketsandMarkets, the IoT-enabled process machinery market is expected to reach $80 billion by 2025, with a compound annual growth rate of 11%. The ability to collect and analyze real-time data allows companies to optimize machine performance, predict maintenance needs, and minimize downtime, proving invaluable in maintaining competitive advantage.

Tips: To stay ahead in the rapidly evolving industry, companies should invest in training their workforce to adapt to new technologies. Additionally, businesses should consider implementing IoT solutions gradually, starting with pilot projects to assess their impact before full-scale deployment. Emphasizing a culture of innovation can also motivate employees to embrace these changes and contribute to the ongoing evolution of process machinery.

Sustainability Practices Shaping the Future of Industrial Machinery

As industries evolve, sustainability practices are becoming central to the operation and innovation of industrial machinery. In 2023, companies are increasingly adopting greener technologies, focusing on reducing their carbon footprint and waste. This shift not only meets regulatory requirements but also caters to a growing consumer demand for environmentally responsible manufacturing processes. By implementing energy-efficient systems and utilizing renewable resources, businesses can significantly mitigate their impact on the environment while potentially reducing operational costs.

Tips for implementing sustainable practices include conducting a thorough energy audit to identify areas for improvement. This can help pinpoint energy wastage and the incorporation of eco-friendly solutions. Moreover, investing in training programs for employees ensures that everyone is aligned with the sustainability goals, fostering a culture of responsibility and awareness throughout the organization.

Another important aspect is the circular economy, encouraging companies to design machinery with a lifecycle mindset. This means creating machines that are easier to repair, recycle, and repurpose, thereby extending their usefulness. Companies can also engage in partnerships with suppliers who prioritize sustainability, ensuring that every part of the supply chain adheres to green principles. By embracing these sustainability practices, industries can drive innovation while playing a crucial role in protecting our planet for future generations.

The Rise of Automation and Artificial Intelligence in Production

The rise of automation and artificial intelligence (AI) has significantly transformed the landscape of production in 2023, marking a pivotal shift in process machinery trends. As industries grapple with increasing demands for efficiency and precision, automation technologies are streamlining production processes and diminishing the likelihood of human error. Advanced robotics, coupled with intelligent software systems, are now capable of performing complex tasks that were once the domain of human operators. This integration not only enhances productivity but also facilitates real-time data analysis, allowing businesses to make informed decisions on the fly.

Furthermore, the synergy between automation and AI is fostering a new era of predictive maintenance. By leveraging machine learning algorithms, companies can anticipate equipment failures before they occur, minimizing downtime and optimizing resource allocation. This proactive approach empowers industries to maintain a competitive edge by reducing operational costs and increasing overall efficiency. As organizations continue to invest in these technologies, the potential for innovation and advancement in process machinery is boundless, encouraging a focus on sustainable, smart manufacturing practices that are reshaping the industry for years to come.

Impact of Industry 4.0 on Process Machinery Efficiency

Industry 4.0 has brought about a significant transformation in the realm of process machinery, focusing on enhancing efficiency across various sectors. At the heart of this evolution is the integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics. These technologies enable real-time monitoring and control of machinery, allowing for predictive maintenance and minimizing downtime. By leveraging data-driven insights, manufacturers can optimize production processes and improve resource allocation, ultimately leading to more efficient operations.

Moreover, the shift towards automation and interconnected systems enhances the overall workflow within industrial environments. Smart machinery, equipped with sensors and connectivity features, can communicate seamlessly with other devices, fostering a synchronized production line. This interconnectivity not only streamlines operations but also facilitates better decision-making through data sharing and collaborative analytics. As industries continue to adopt these advanced technologies, the efficiency gains from Industry 4.0 are expected to become a defining characteristic of process machinery, setting a new standard for productivity and operational excellence.

Impact of Industry 4.0 on Process Machinery Efficiency in 2023

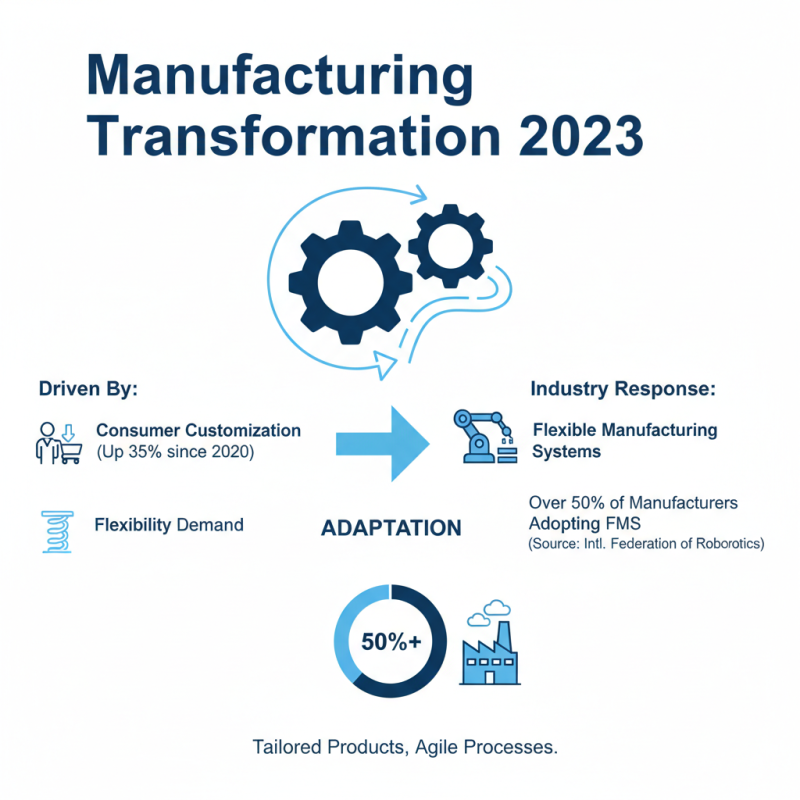

Trends in Customization and Flexibility in Manufacturing Equipment

In 2023, the manufacturing industry is undergoing significant transformation, primarily driven by trends in customization and flexibility. A recent report from the International Federation of Robotics highlights that over 50% of manufacturers are increasingly adopting flexible manufacturing systems to cater to consumer demand for tailored products. This shift is in response to the modern consumer's preference for customization, which has surged by 35% since 2020, indicating a clear need for adaptable processes in machinery design.

Moreover, advancements in technology, such as Artificial Intelligence and Machine Learning, are revolutionizing how machinery adapts to varying production requirements. According to a study by the World Economic Forum, nearly 70% of manufacturers reported that integrating AI into their processes has enhanced their ability to provide customized solutions rapidly. This adaptability not only reduces lead times but also minimizes waste, aligning with sustainability goals that are becoming increasingly pertinent in the industry. The trends toward customization and flexibility in manufacturing equipment are not just enhancing competitive advantage; they are redefining operational standards in the sector, paving the way for a more responsive and efficient production landscape.

Related Posts

-

Top 10 Process Machinery Types You Should Know for Your Business

-

What is Manufacturing Machines and How They Revolutionize Production

-

Top 10 Benefits of Using Automation Machines for Your Business Efficiency

-

Mastering Finishing Systems: A Comprehensive Guide to Enhancing Product Quality and Performance

-

How to Succeed in Industrial Engineering with Essential Skills and Techniques

-

Unlocking the Potential of Vibratory Polishing Machines: Tips for Optimal Performance and Maintenance