How to Succeed in Industrial Engineering with Essential Skills and Techniques

In today's rapidly evolving industrial landscape, the role of industrial engineering has become increasingly vital for organizations aiming to enhance efficiency and productivity. Industrial engineering merges principles from engineering, management, and systems thinking, creating a unique approach to optimizing complex processes and systems. As industries face challenges such as globalization, technological advancements, and the need for sustainability, professionals equipped with essential skills and techniques in industrial engineering are well-positioned to drive innovation and improve operations.

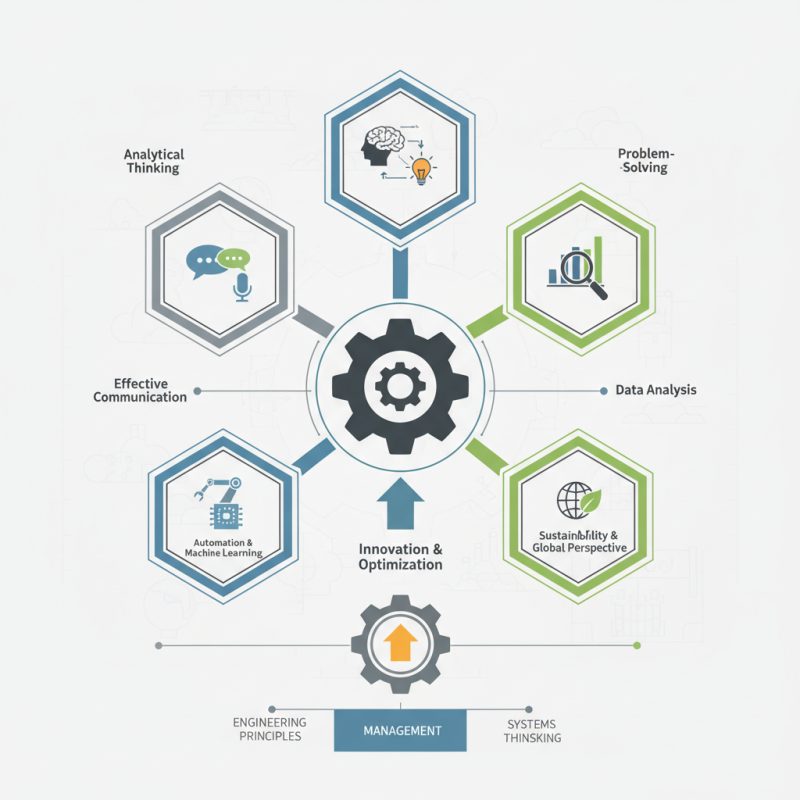

To excel in the field of industrial engineering, aspiring engineers must cultivate a robust skill set that encompasses analytical thinking, problem-solving abilities, and effective communication. Additionally, proficiency in data analysis and an understanding of modern technologies, such as automation and machine learning, are indispensable in today's data-driven environment. This article will explore these critical skills and techniques that pave the way for success in industrial engineering, illustrating how a strategic approach can lead to both individual and organizational achievements in various industrial sectors. By mastering these competencies, professionals can ensure their relevance and impact in a dynamic workplace, ultimately contributing to the advancement of their organizations and the industry as a whole.

Key Competencies Required for Success in Industrial Engineering

To succeed in industrial engineering, certain key competencies are essential. Firstly, a strong foundation in mathematics and data analysis is crucial. Industrial engineers often work with complex datasets, requiring proficiency in statistical methods and tools to interpret and manipulate data effectively. This analytical ability allows engineers to identify inefficiencies in systems and processes, ultimately leading to improved productivity and cost savings.

Additionally, knowledge of systems thinking and process optimization techniques is vital. Industrial engineers must understand how to evaluate entire systems rather than just individual components. This holistic approach enables them to design effective workflows, implement quality control measures, and streamline operations. Furthermore, strong communication skills are necessary, as industrial engineers often collaborate with cross-functional teams, stakeholders, and management to identify problems and implement solutions. By combining technical expertise with interpersonal skills, industrial engineers can facilitate better decision-making and drive organizational success.

How to Succeed in Industrial Engineering with Essential Skills and Techniques - Key Competencies Required for Success in Industrial Engineering

| Competency | Description | Importance Level | Recommended Techniques |

|---|---|---|---|

| Analytical Skills | Ability to analyze complex data and situations to make informed decisions. | High | Data analysis software, Statistical methods |

| Project Management | Skills to effectively manage projects from initiation to completion. | High | Gantt charts, Agile methodologies |

| Communication Skills | Ability to clearly convey ideas and information to a variety of audiences. | Medium | Presentation techniques, Written communication |

| Teamwork | Working collaboratively with diverse groups to achieve common goals. | High | Team-building activities, Conflict resolution strategies |

| Technical Proficiency | Knowledge of engineering tools and technologies relevant to the field. | High | Software training, Continuous education |

| Problem-Solving | Ability to identify problems and implement effective solutions. | High | Root cause analysis, Brainstorming techniques |

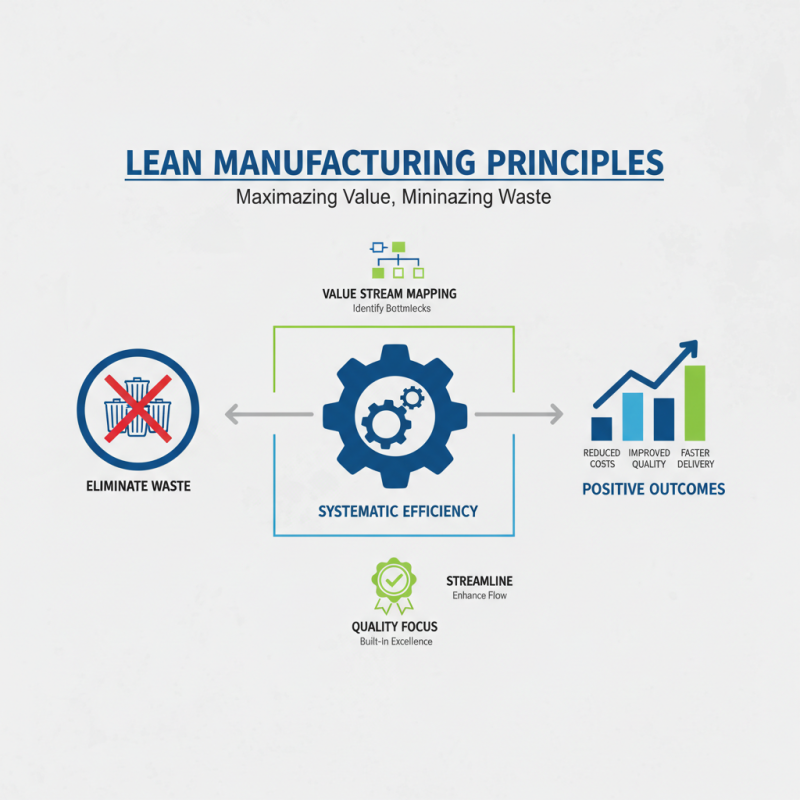

Understanding Lean Manufacturing Principles and Their Applications

Lean manufacturing principles are essential in industrial engineering as they focus on maximizing value while minimizing waste. At its core, lean manufacturing emphasizes efficiency through the systematic elimination of non-value-adding activities. By applying techniques such as value stream mapping, engineers can identify bottlenecks and streamline processes, ensuring that every step in production contributes positively to the end result. This systematic approach not only reduces costs but also enhances product quality and delivery speed.

Furthermore, lean principles foster a culture of continuous improvement and collaboration among team members. Engaging employees in problem-solving and decision-making helps cultivate an environment where innovation can thrive. Tools such as the "5S" methodology—Sort, Set in order, Shine, Standardize, and Sustain—are practical strategies that reinforce organization and discipline in the workplace. By embedding these practices into the organizational framework, industrial engineers can not only improve operational performance but also create a more agile and responsive organization capable of adapting to market changes.

Data Analysis and Statistical Methods: A Foundation for Decision Making

In today's fast-paced industrial environment, mastering data analysis and statistical methods is crucial for effective decision-making. Industrial engineering professionals utilize these skills to optimize processes, enhance productivity, and reduce costs. According to the Bureau of Labor Statistics, employment in industrial engineering is projected to grow by 10% from 2020 to 2030, highlighting the increasing reliance on data-driven strategies in the industry. By leveraging data to inform their decisions, engineers can identify inefficiencies and propose actionable solutions that drive organizational success.

To effectively harness data analysis, practitioners should focus on developing their statistical skills. Techniques such as regression analysis, hypothesis testing, and quality control charts empower engineers to draw meaningful conclusions from data sets and support evidence-based decisions. A report by Deloitte indicates that organizations that prioritize data analysis in their operations experience a 5-6% improvement in overall performance, underscoring the necessity of integrating these techniques into everyday practices.

Project Management Techniques in Industrial Engineering: Best Practices

Project management is a critical component of industrial engineering, where the ability to effectively plan, execute, and oversee processes can significantly influence a project's success. According to a report by the Project Management Institute (PMI), organizations with mature project management practices waste about 28 times less money than those with poorly managed processes. This highlights the importance of utilizing best practices in project management to enhance productivity and reduce operational costs in industrial settings.

One highly effective technique is the Agile project management approach, which emphasizes flexibility and iterative progress assessments. A study by the Standish Group identified that Agile methodologies can increase project success rates by up to 40% compared to traditional methods. This adaptability allows industrial engineers to respond rapidly to changing requirements and optimize resource allocation, ensuring that projects are not only completed on time but also meet client expectations. Moreover, tools such as Gantt charts and project management software facilitate better visualization and tracking of project timelines and deliverables, helping teams maintain focus and accountability.

Incorporating continuous improvement practices, such as Lean and Six Sigma, further strengthens project management in industrial engineering. These methodologies promote waste reduction and process optimization, leading to enhanced efficiency and quality. According to a study published in the International Journal of Production Research, organizations that implement Lean practices experience a significant decrease in process cycle times by up to 50%. By integrating these best practices into project management strategies, industrial engineers can ensure that they lead their teams toward successful and sustainable outcomes.

Emerging Technologies Transforming the Industrial Engineering Landscape

Emerging technologies are profoundly reshaping the landscape of industrial engineering, fostering innovative approaches to solve complex problems within various industries. Today, advancements such as artificial intelligence, the Internet of Things (IoT), and big data analytics are becoming essential tools for industrial engineers. These technologies enhance decision-making processes, optimize operations, and improve efficiency, making it crucial for professionals in the field to stay abreast of these changes.

Tips: To effectively adapt to these technological shifts, consider enhancing your technical skill set. Familiarize yourself with data analysis software and machine learning algorithms. Engaging in online courses or certifications can provide you with a solid foundation in these areas.

Furthermore, collaboration tools powered by emerging technologies can facilitate better teamwork and communication, which are vital in industrial engineering projects. Embrace cloud-based platforms to share information in real-time and utilize virtual simulations to predict project outcomes.

Tips: Networking with professionals in tech-oriented roles can also provide insights into integrating new technologies into your practice. Join industry forums and attend workshops to exchange ideas and best practices with peers who are navigating similar challenges.

Related Posts

-

How to Succeed in Industrial Engineering Careers and Master Key Skills

-

Why You Should Choose Dalal Vibro Finishing Machine for Superior Surface Finishing

-

Why Automation Machines Are Essential for Modern Manufacturing Success

-

Top 10 UK Manufacturing Trends Transforming the Industry in 2023

-

2025 Top Vibratory Finishing Machine Trends and Best Options

-

Top 10 Essential Manufacturing Machines Revolutionizing Production Efficiency