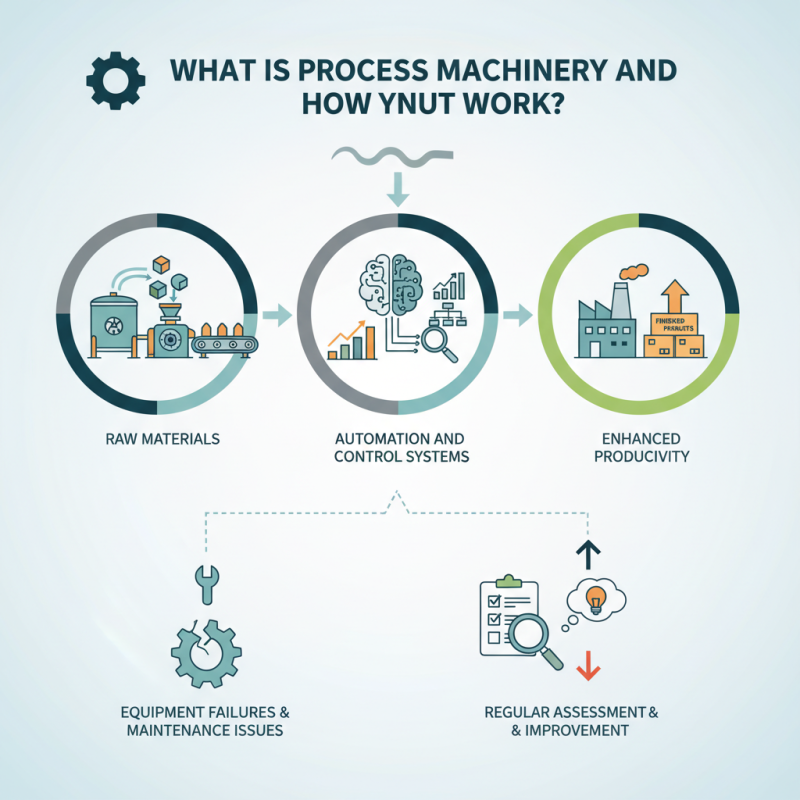

What is Process Machinery and How Does it Work?

Process machinery plays a vital role in various industries. It encompasses the equipment used for manufacturing, processing, and packaging goods. According to industry expert Dr. Emily Thompson, "Process machinery is the backbone of production efficiency." This statement highlights the importance of these systems in optimizing operations.

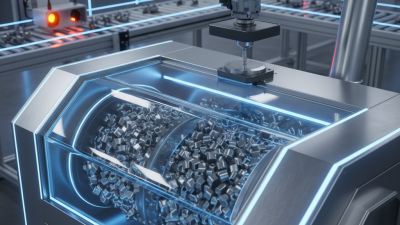

In manufacturing plants, process machinery ensures smooth workflows. Machines like mixers, grinders, and conveyers work together to transform raw materials into finished products. Each machine has a specific role, contributing to overall productivity. However, challenges often arise, such as equipment failures and maintenance issues. These problems can disrupt operations, leading to financial losses.

Understanding how process machinery functions is crucial. It not only involves mechanical aspects but also automation and control systems. The integration of technology can improve performance but requires ongoing analysis. Regular assessments can identify inefficiencies and areas for improvement. In the pursuit of enhanced productivity, companies must reflect on their process machinery strategies.

Definition and Overview of Process Machinery

Process machinery refers to the equipment used in various industrial processes. It plays a crucial role in transforming raw materials into finished products. This machinery is vital in sectors like food processing, pharmaceuticals, and chemicals. Each machine is designed for specific tasks, ensuring efficiency and precision in production.

Different types of process machinery include mixers, conveyors, and reactors. Mixers blend materials to achieve a uniform product. Conveyors move materials through different stages of production. Reactors facilitate chemical reactions needed to produce desired compounds. Understanding these machines helps optimize production lines. It's important to regularly maintain machinery to avoid costly downtimes.

Despite their importance, many industries still struggle with process machinery. Inefficient machines can lead to waste and increased costs. Operators may not fully understand how to optimize their use. This can result in underperformance or safety risks. Continuous training and evaluation are needed for improvement. Observing and reflecting on operational practices can lead to better outcomes.

Process Machinery Overview

Key Components of Process Machinery and Their Functions

Process machinery plays a crucial role in various industries, from manufacturing to food processing. Understanding its key components helps optimize performance. Among these components, pumps are essential for moving liquids. They are vital in processes like chemical mixing. According to a recent industry report, the global pump market is expected to exceed $68 billion by 2025.

Another important component is heat exchangers. They transfer heat between fluids, crucial for maintaining desired temperatures. Inefficiencies in heat exchangers can lead to significant energy loss. A study found that optimizing these systems can reduce energy consumption by up to 30%.

**Tip:** Regularly inspect your machinery to identify worn components. Make timely repairs to avoid larger issues down the line.

Valves also play a critical role in controlling fluid flow. They ensure processes run smoothly and safely. However, improper valve selection can disrupt operations. Choosing the right valve type based on pressure and flow requirements is essential.

**Tip:** Train staff on proper valve handling. Human error can lead to costly mistakes.

Understanding these components allows for better machinery operation and maintenance. Each part contributes to overall efficiency. Failing to recognize their importance can lead to unexpected downtimes and financial losses.

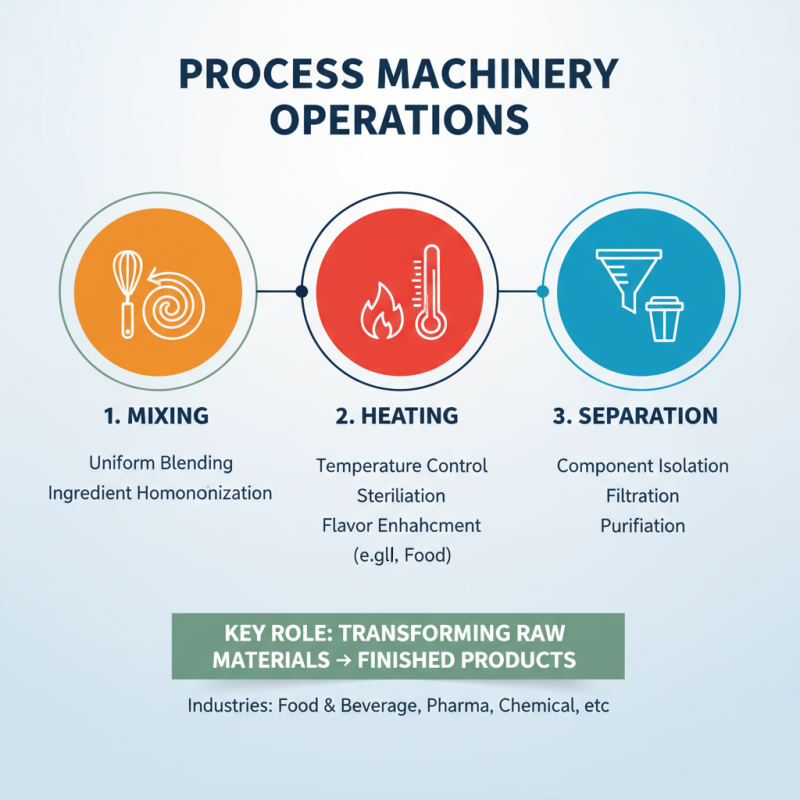

The Working Principles Behind Process Machinery Operations

Process machinery plays a vital role in various industries, from food and beverage to pharmaceuticals. The working principles behind these machines hinge on three main operations: mixing, heating, and separation. These processes transform raw materials into finished products. For instance, in food processing, heat transfer can elevate food safety and enhance flavors.

The efficiency of process machinery significantly affects production costs. According to industry studies, optimizing machinery can lead to a 20% increase in productivity. Regular maintenance is also crucial; neglecting it can result in breakdowns and costly repairs. Manufacturers often overlook this aspect, leading to reduced overall efficiency.

**Tip:** Keep an eye on the maintenance schedule. It saves both time and money.

Understanding the flow of material and energy within these systems aids in improving overall operational efficiency. Elements like pumps and conveyors must be synchronized effectively. However, many operations struggle with this balance, resulting in wasted resources and time. Identifying bottlenecks early can help refine processes.

**Tip:** Assess operations weekly. Minor adjustments can have significant impacts.

Types of Process Machinery in Different Industries

Process machinery is essential in various industries, enabling efficient production and operational processes. In the food and beverage sector, for instance, equipment like mixers and extruders plays a critical role. Mixers help blend ingredients uniformly, ensuring consistent product quality. Extruders shape raw materials into specific forms. These machines must be maintained regularly to avoid contamination and production delays.

In the chemical industry, reactors and separators are vital. Reactors facilitate chemical reactions under controlled conditions. Sometimes, they can malfunction, leading to safety risks. Separators are used to separate different components after reactions. Their efficiency is crucial for product purity. If not monitored closely, these tools can lead to increased waste and reduced output quality.

The pharmaceutical industry relies heavily on coating machines and tablet presses. Coating machines ensure pills have a consistent outer layer, impacting absorption rates. Tablet presses, on the other hand, must exert precise pressure to avoid inconsistencies. A small error can lead to dosage variations, impacting efficacy. Regular training for operators is essential to minimize these risks. Each type of machinery has its own challenges, which need consistent evaluation.

What is Process Machinery and How Does it Work? - Types of Process Machinery in Different Industries

| Type of Process Machinery | Industry | Function | Key Features |

|---|---|---|---|

| Pumps | Oil & Gas | Transporting liquids | High efficiency, reliability |

| Mixers | Food Processing | Mixing ingredients | Variable speed, easy cleaning |

| Conveyors | Manufacturing | Transporting materials | Durability, adjustable speed |

| Heat Exchangers | Chemical Processing | Heat transfer between fluids | Compact design, high thermal efficiency |

| Reactors | Pharmaceuticals | Chemical reactions | Controlled environment, pressure resistance |

| Filtration Systems | Water Treatment | Removing impurities | High filtration efficiency, low maintenance |

Applications and Benefits of Process Machinery in Production Processes

Process machinery plays a critical role in various production processes across multiple industries. It encompasses a wide range of equipment and technology designed to facilitate the transformation of raw materials into finished products. From mixing and blending to heating and cooling, each piece of machinery performs a specific function. This ensures efficiency and precision in manufacturing.

The applications of process machinery are vast. In food processing, machinery helps in creating everything from packaged snacks to canned goods. In the chemical industry, it enables the safe mixing of substances. These machines enhance productivity, cut down waste, and ensure consistent quality. However, the integration of such machinery brings challenges. Maintenance can be demanding, and unexpected breakdowns may disrupt operations. Industries must often weigh investment costs against potential losses.

Additionally, process machinery contributes to sustainability efforts. Automation reduces energy consumption, minimizing environmental impacts. But there’s a catch—over-reliance on machinery can lead to skill gaps in the workforce. As technology advances, operators need ongoing training to stay effective. Balancing automation with human insight is essential. Thoughtful integration of process machinery can drive innovation and set the stage for future improvements.

Related Posts

-

What is Manufacturing Machines and How They Revolutionize Production

-

Top 10 Process Machinery Types You Should Know for Your Business

-

Top 10 Essential Manufacturing Machines Revolutionizing Production Efficiency

-

Top 10 Process Machinery Trends Transforming Your Industry in 2023

-

Top 10 Manufacturing Machines You Need to Know for Your Business Growth

-

2025 Top Vibratory Finishing Machine Trends and Best Options