What is Manufacturing Machines and How They Revolutionize Production

In the contemporary manufacturing landscape, the use of advanced manufacturing machines has become a cornerstone of operational efficiency and productivity. According to a report by the International Federation of Robotics, the global industrial robot market is projected to reach over $70 billion by 2025, underscoring the pivotal role these machines play in revolutionizing production processes. This surge in automation not only enhances precision and consistency but also mitigates human error, leading to significant cost savings and improved product quality.

Furthermore, a study from McKinsey highlights that companies adopting smart manufacturing technologies—including advanced robotics, IoT, and AI-driven machinery—could see productivity gains of 20-30%. This transformation is not merely a trend; it represents a fundamental shift in how goods are produced, with manufacturing machines becoming more intelligent and interconnected. As industries pivot towards sustainability and agility, harnessing the capabilities of these state-of-the-art machines is essential for remaining competitive in an increasingly global market. Thus, understanding the evolution and impact of manufacturing machines is crucial for businesses aiming to thrive in this new era of production.

The Definition and Role of Manufacturing Machines in Modern Industry

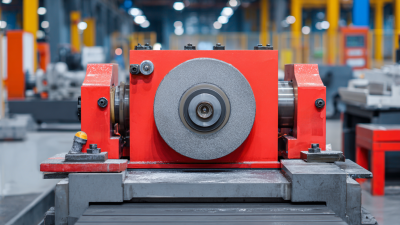

Manufacturing machines are the backbone of modern industry, playing a pivotal role in enhancing production efficiency and product quality. Defined as automated tools and equipment utilized in the creation of goods, these machines range from CNC (Computer Numerical Control) machines to 3D printers.

According to a report by the International Federation of Robotics, the global sales of industrial robots reached approximately 384,000 units in 2020, reflecting a surge in automation adoption for manufacturing processes. This integration of advanced machinery allows manufacturers to streamline operations, reduce labor costs, and significantly minimize errors.

In recent years, the role of manufacturing machines has expanded beyond traditional assembly lines to embrace smart technologies. The rise of Industry 4.0 has prompted a shift towards interconnected machines that communicate and optimize production in real time. A study by McKinsey & Company highlights that implementing digital technologies in manufacturing could increase productivity by up to 30% by 2030. This evolution underscores the transformative impact of manufacturing machines not only in ramping up production capabilities but also in fostering innovation and competitiveness within the industry.

Key Technologies Behind Manufacturing Machines: Automation, Robotics, and IoT

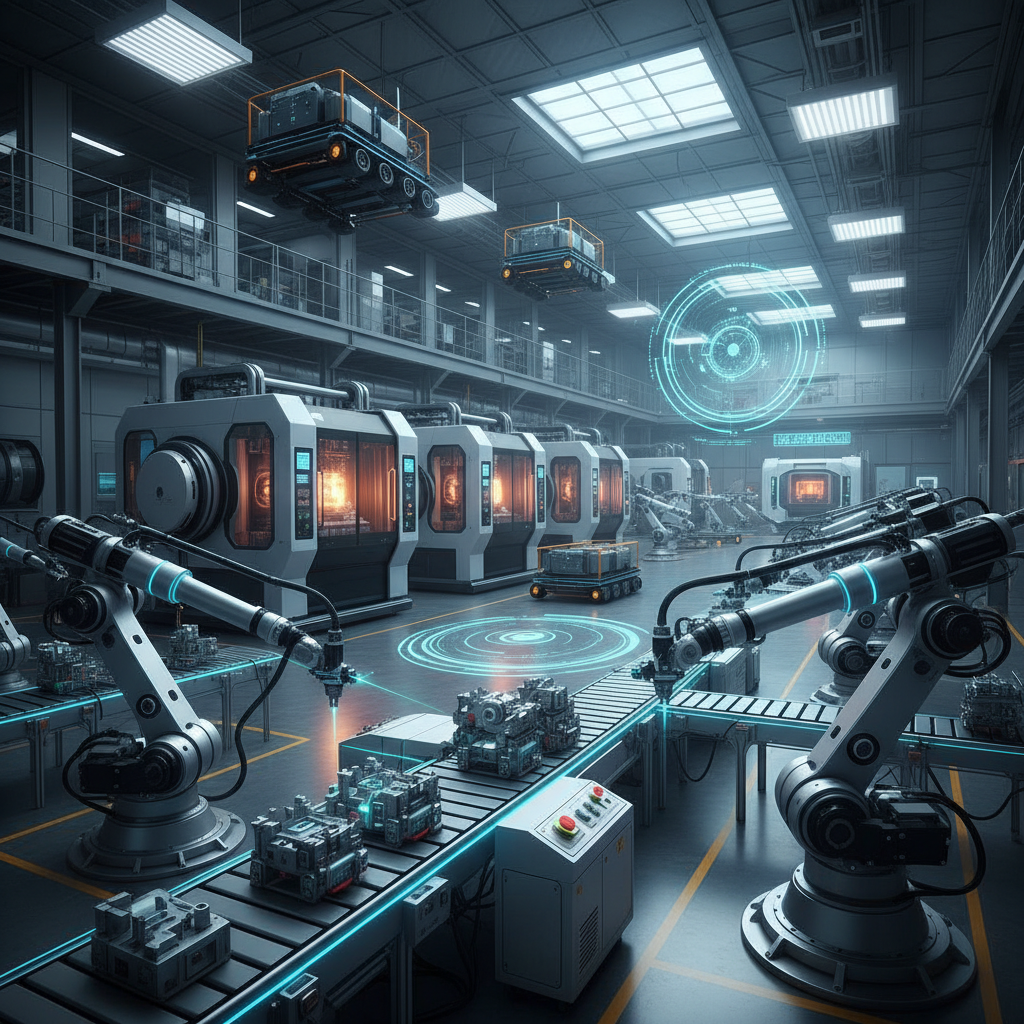

Manufacturing machines have dramatically transformed production landscapes by integrating advanced technologies such as automation, robotics, and the Internet of Things (IoT). As industries face challenges like labor shortages and fluctuating demands, intelligent manufacturing offers solutions that streamline operations and enhance efficiency. The global smart manufacturing market is projected to grow from $394.35 billion in 2025 to $998.99 billion by 2032, reflecting an impressive annual growth rate of 14.2%. This surge underscores the increasing reliance on technology to optimize production processes.

Key technologies driving this revolution include industrial robots, control devices, and sensors that work collaboratively to create smart factories. These systems not only improve productivity but also ensure precise quality control and resource management. For example, in process industries, automation is essential for tasks like mixing and boiling, which rely on specific formulas—once combined, these ingredients cannot be separated. Such advancements highlight the critical role of automation and IoT in modern manufacturing, enabling businesses to remain competitive in an ever-evolving market.

Impact of Manufacturing Machines on Production Efficiency and Cost Reduction

Manufacturing machines play a pivotal role in enhancing production efficiency across various industries. By automating repetitive tasks, these machines minimize human error and increase precision. For instance, CNC (Computer Numerical Control) machines can produce components with exact specifications, drastically reducing the time required for manual adjustments. This translates to quicker turnaround times, allowing manufacturers to meet customer demands more effectively and respond to market changes swiftly.

Furthermore, the integration of advanced manufacturing machines leads to significant cost reductions. Automated processes often require fewer labor hours, allowing companies to allocate resources to other critical areas such as research and development. Additionally, these machines optimize the use of raw materials, resulting in less waste and lower material costs. The ability to scale production without proportional increases in costs further demonstrates how manufacturing machines not only streamline operations but also enhance a company’s competitiveness in a rapidly evolving economic landscape.

Statistics on the Growth of Manufacturing Machines Market and Future Trends

The manufacturing machines market is experiencing significant growth, largely driven by advancements in digital manufacturing technologies. These innovations have transformed various industries by enhancing productivity and operational efficiency. Notably, advanced machine learning algorithms have emerged as a game-changer in forecasting demand. By analyzing extensive datasets, these AI-based tools can identify seasonal trends, thereby improving prediction accuracy and efficiency. This ensures that manufacturers can meet market demands more effectively, minimizing waste and optimizing resources.

Tips: When implementing AI forecasting tools, ensure that your data is clean and well-organized to achieve the best results. Additionally, consider regular updates to your forecasting models to adapt to changing market dynamics.

The global semiconductor equipment manufacturing market is projected to reach a staggering size of USD 218.60 billion by 2033, growing at a compound annual growth rate (CAGR) of 7.78%. This growth reflects the increasing reliance on semiconductor devices across various sectors, further underscoring the importance of investing in advanced manufacturing technologies. As the landscape continues to evolve, businesses must stay informed about emerging trends and technological advancements to maintain a competitive edge.

Tips: Keep track of the latest industry reports and market analyses to stay informed about upcoming trends. Networking with industry leaders can also provide valuable insights into best practices and emerging technologies in the manufacturing sector.

Challenges and Innovations in the Adoption of Advanced Manufacturing Technologies

The adoption of advanced manufacturing technologies brings both exciting opportunities and formidable challenges. One significant hurdle companies face is the high initial investment required for cutting-edge manufacturing machines. Many businesses, especially small and medium-sized enterprises, struggle to allocate funds for upgrading their equipment, which can deter them from implementing new technologies. Additionally, the rapid pace of technological advancement means that companies must continuously invest to keep up, which can be daunting and financially taxing.

Moreover, integrating new technologies into existing production processes can lead to operational disruptions. Employees may require extensive training to adapt to innovative systems, and there might be resistance to change among the workforce. Manufacturers must address these challenges by fostering a culture of continuous learning and development, ensuring that staff are well-equipped to utilize modern machinery. As innovations in automation and artificial intelligence reshape the industry, companies must strive to balance investment in technology with workforce preparedness to fully harness the benefits of advanced manufacturing.

Impact of Advanced Manufacturing Technologies on Production Efficiency

Related Posts

-

Top 10 Essential Manufacturing Machines Revolutionizing Production Efficiency

-

Mastering Finishing Systems: A Comprehensive Guide to Enhancing Product Quality and Performance

-

Top 10 Vibratory Polishing Machines for Perfect Finishing

-

Top 10 UK Manufacturing Trends Transforming the Industry in 2023

-

Unlocking the Potential of Vibratory Polishing Machines: Tips for Optimal Performance and Maintenance

-

Why Automation Machines Are Essential for Modern Manufacturing Success