Why You Should Invest in a Vibratory Polishing Machine for Your Business

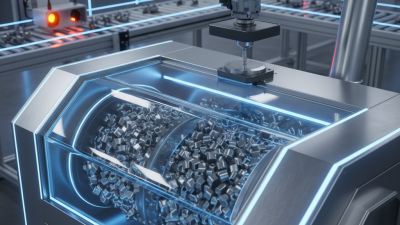

Investing in a vibratory polishing machine can be a transformative decision for your business, particularly if you operate in manufacturing, jewelry, or metalworking industries. These machines are designed to enhance the finishing processes by providing uniform surface polishing, reducing labor costs, and increasing overall efficiency. With the ability to handle various materials and shapes, a vibratory polishing machine offers versatility that is essential for businesses aiming to improve product quality while maintaining competitive pricing.

Furthermore, the use of a vibratory polishing machine can significantly streamline production workflows. Unlike traditional polishing methods, which may be labor-intensive and time-consuming, vibratory polishing machines utilize automated systems to produce consistent results faster. This not only enhances productivity but also minimizes the risk of human error, ensuring that every piece meets the high standards expected by customers. As your business strives to maintain a strong market presence, integrating such advanced technology can be a key factor in driving growth and satisfying customer demands.

In summary, the strategic investment in a vibratory polishing machine is not merely about upgrading equipment; it represents a commitment to quality, efficiency, and innovation. By embracing this technology, your business can position itself to thrive in an increasingly competitive landscape, offering superior products that resonate with your clientele.

Benefits of Vibratory Polishing Machines for Industrial Applications

Vibratory polishing machines are becoming essential tools in various industrial applications due to their efficiency and versatility. According to a recent market report from Allied Market Research, the global vibratory finishing equipment market is projected to reach $1.6 billion by 2027, indicating strong growth driven by enhanced productivity and reduced labor costs. These machines employ a combination of vibration and abrasives to effectively polish, deburr, and clean parts, making them suitable for various materials, including metals and plastics. This adaptability allows businesses to streamline their processes, leading to increased output and improved product quality.

In addition to operational efficiency, vibratory polishing machines offer significant cost benefits. Data from the International Journal of Advanced Manufacturing Technology highlights that companies utilizing these systems can reduce processing times by up to 50% compared to traditional methods, allowing for more rapid turnaround on projects. Furthermore, the automated nature of these machines minimizes labor-intensive tasks, leading to reduced manpower costs and the potential for reallocation of workers to more value-added activities. As industries increasingly focus on sustainability and waste reduction, vibratory polishing provides an eco-friendly solution by ensuring minimal abrasive waste and energy consumption, ultimately supporting greener manufacturing practices.

Key Features to Look for When Choosing a Vibratory Polishing Machine

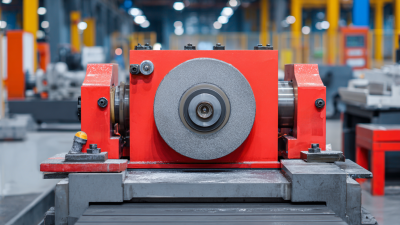

When selecting a vibratory polishing machine for your business, several key features should be carefully considered to ensure you make the right investment. Firstly, the machine's capacity and size play a significant role. Depending on the volume of parts you process, choose a machine that can accommodate your workload efficiently. A larger bowl size typically allows for a higher batch capacity, which can enhance productivity and meet the demands of larger orders.

Additionally, look for machines with adjustable processing capabilities, including variable speed settings and customizable vibration intensity. This versatility allows you to tailor the polishing process to different materials and finishes, ensuring optimal results. Moreover, consider the construction quality of the machine; durable materials will increase its lifespan and reliability, minimizing maintenance costs over time. Don’t forget to examine the filtration system—an effective filtration mechanism is crucial for maintaining cleanliness during the polishing process, reducing contaminants in the media, and ensuring a high-quality finish on the workpieces.

Comparative Analysis: Vibratory Polishing vs. Traditional Polishing Methods

Vibratory polishing machines have revolutionized the way businesses approach finishing processes. Unlike traditional polishing methods, such as hand polishing or rotary tumbling, vibratory polishing offers enhanced efficiency and consistency. According to a recent industry report, businesses that implement vibratory polishing techniques can see a time reduction of up to 50% in finishing processes, leading to increased productivity and reduced labor costs. Traditional methods often fall short in uniformity, resulting in variations that may compromise product quality. In contrast, vibratory polishing ensures a more uniform finish, significantly improving the aesthetic appeal and durability of parts.

When considering the switch to vibratory polishing, businesses should focus on a few key tips. First, evaluate the size and volume of parts to determine the scale of the vibratory machine needed. Second, assess the type of media being used, as different media can dramatically affect the polishing results, providing a tailored finish for various applications. Additionally, monitoring the wear of polishing media can help maintain optimal performance and prevent costly downtime. According to a study, companies that regularly update their media experience a consistent improvement in finishing quality, with some reporting up to a 30% enhancement in surface finish.

Ultimately, the advantages of vibratory polishing extend beyond just time savings. The ability to automate processes not only frees up labor resources but also provides a safer working environment by reducing manual handling of materials. As industries continue to evolve, investing in advanced polishing methods such as vibratory polishing will position businesses for sustained competitiveness and growth.

Why You Should Invest in a Vibratory Polishing Machine for Your Business

| Feature | Vibratory Polishing | Traditional Polishing |

|---|---|---|

| Cycle Time | Less than 1 hour | Several hours |

| Surface Finish Quality | High-quality finish | Variable quality |

| Labor Intensity | Low | High |

| Material Compatibility | Wide range of materials | Limited to certain materials |

| Environmental Impact | Lower dust and waste | Higher dust and waste |

| Initial Investment | Moderate | Low to Moderate |

| Maintenance | Low | Moderate to High |

Cost-Benefit Assessment of Investing in Vibratory Polishing Technology

Investing in a vibratory polishing machine can yield significant returns for your business, particularly when evaluated through a cost-benefit lens. These machines not only enhance the efficiency of the polishing process but also reduce labor costs associated with manual polishing methods. The initial investment may seem daunting; however, the long-term savings in labor, increased production capacity, and improved product quality typically offset these costs. By automating the polishing process, businesses can achieve consistent finishes that meet high-quality standards while freeing up valuable staff time for more strategic tasks.

Tips for evaluating the cost-effectiveness of a vibratory polishing machine include analyzing current labor costs and identifying how much time is spent on manual polishing. Calculate the potential decrease in working hours and the corresponding reduction in labor expenses. Additionally, consider the volume of products that can be processed with the machine versus your current method. This helps in forecasting potential revenue growth due to increased production capabilities.

It’s also essential to consider the long-term benefits of product quality and consistency. A vibratory polishing machine not only provides a uniform finish but also minimizes material waste, which is often a hidden cost in manual polishing. Before making a purchase, gather feedback from industry peers already utilizing this technology to understand their experiences and potential hidden costs.

Real-World Applications and Success Stories of Vibratory Polishing Machines

Vibratory polishing machines offer a range of real-world applications that can significantly enhance operational efficiency and product quality across various industries. Automotive manufacturers, for example, use these machines to achieve a high-gloss finish on metal components, resulting in improved aesthetics and corrosion resistance. In jewelry production, vibratory polishing allows for the gentle finishing of pieces, ensuring that intricate designs retain their detail while achieving a polished look that attracts customers. Additionally, in the aerospace sector, these machines are employed to deburr and smooth components, enhancing performance and extending the lifecycle of critical parts.

When considering a vibratory polishing machine for your business, it’s essential to keep a few tips in mind. First, assess the specific needs of your production process—understanding what materials you'll be working with and the desired finish can guide you in selecting the right machine. Second, invest time in training your team on the machine's operation; proper handling can lead to improved results and a longer lifespan for the equipment. Lastly, establish a regular maintenance schedule to ensure optimal performance and prevent downtime, which is critical for maintaining productivity.

The success stories of various industries utilizing vibratory polishing machines illustrate the potential benefits for businesses willing to invest in this technology. Companies have reported increased throughput and reduced labor costs, highlighting the important role these machines play in modern manufacturing environments. By streamlining finishing processes and enhancing product quality, vibratory polishing machines are proving to be invaluable assets in the competitive landscape.

Related Posts

-

Unlocking the Potential of Vibratory Polishing Machines: Tips for Optimal Performance and Maintenance

-

Top 10 Vibratory Polishing Machines for Perfect Finishing

-

How to Choose the Best Centrifugal Disc Finishing Machine for Your Needs

-

Top 10 Benefits of Using Vibro Machines for Effective Workouts

-

2025 Top Vibratory Finishing Machine Trends and Best Options

-

Top 10 Benefits of Using PLC Control Panels in Industrial Automation