Top 10 Essential Manufacturing Machines Revolutionizing Production Efficiency

In today's rapidly evolving industrial landscape, the integration of advanced manufacturing machines has become crucial for enhancing production efficiency. According to a report by the International Federation of Robotics (IFR), global sales of industrial robots increased by 12% in 2021, indicating a growing commitment to automation within manufacturing settings. These technological advancements not only streamline operations but also significantly reduce labor costs and improve product quality. For example, manufacturers utilizing state-of-the-art CNC machines have reported a 30% increase in productivity when compared to traditional methods.

As industries strive to stay competitive in a market characterized by escalating demands and short lead times, understanding which manufacturing machines are essential becomes imperative. By identifying and implementing the top machines revolutionizing production, manufacturers can leverage data-driven insights to optimize their workflows. The convergence of digital tools with physical machinery paves the way for smart factories, promoting real-time monitoring and decision-making that enhances operational effectiveness. This article will explore the top 10 essential manufacturing machines that are driving this transformative shift, underscoring the importance of embracing innovation in the pursuit of operational excellence.

The Rise of Automation: Impact of Robotics on Manufacturing Efficiency

The rise of automation in the manufacturing sector has significantly transformed production efficiency, largely driven by advancements in robotics. These machines enhance precision and speed, allowing for higher output with consistent quality. Unlike human workers, industrial robots can operate around the clock without fatigue, reducing the overall production time and minimizing the risk of errors. This capability not only streamlines manufacturing processes but also enables companies to respond swiftly to market demands with less downtime.

Moreover, integrating robotics into the manufacturing workflow is facilitating a shift towards more sophisticated operations. Collaborative robots, or cobots, can work alongside human employees, enhancing their productivity and safety. This synergy allows for a more flexible workforce where machines handle repetitive or hazardous tasks, freeing up human workers for more complex and creative problem-solving roles. As manufacturers increasingly adopt these technologies, the industry is witnessing a marked improvement in efficiency, profitability, and innovation potential, setting a new standard for production in the modern age.

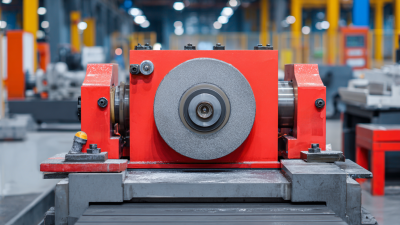

Advanced CNC Machines: Precision and Speed in Modern Production Environments

The manufacturing landscape is undergoing a dynamic transformation, driven largely by the integration of advanced CNC machines that emphasize precision and speed. According to industry reports, CNC technology has the potential to enhance productivity by up to 30% compared to traditional machining methods, allowing manufacturers to meet the increasing demand for high-quality components with minimal lead times. This shift is evident in various sectors, from automotive to aerospace, where the need for precise and efficient production is paramount.

The introduction of next-generation CNC lathes, like the latest offerings from major manufacturers, exemplifies this trend. These machines are engineered to operate at higher speeds while maintaining exceptional accuracy, addressing the challenges posed by complex multi-tasking requirements in today’s production environments. Data suggests that advanced CNC lathes can reduce setup times by as much as 50%, enabling manufacturers to transition seamlessly between different projects and adapt quickly to market shifts. As companies continue to embrace digitalization in manufacturing, the role of these innovative machines will be crucial in maximizing operational efficiency and achieving competitive advantages in the global market.

3D Printing Technology: Transforming Prototyping and Production Processes

In the realm of modern manufacturing, 3D printing technology has emerged as a game changer, transforming both prototyping and production processes. This innovative technique allows for rapid prototyping, enabling companies to develop and test designs in a fraction of the time required by traditional methods. With the ability to create complex geometries and custom features, manufacturers can quickly iterate on their designs, leading to improved product quality and faster time-to-market.

Moreover, 3D printing offers significant cost advantages by reducing material waste and minimizing the need for extensive tooling. Traditional manufacturing processes often involve subtractive methods, where material is removed to create the final product, leading to inefficiencies and excess waste. In contrast, 3D printing is additive, building objects layer by layer, which not only conserves materials but also drastically lowers production costs for small runs and customized products. As more industries adopt this technology, the potential for innovation and increased efficiency in production becomes limitless, reshaping the landscape of manufacturing.

IoT Integration: Enhancing Machinery Performance through Smart Technologies

In the rapidly evolving landscape of manufacturing, integrating Internet of Things (IoT) technologies into machinery is a game-changer for enhancing production efficiency. IoT-enabled machines can communicate with each other and with centralized systems, allowing for real-time monitoring of equipment performance, predictive maintenance, and optimized operation. With the data collected from connected devices, manufacturers can gain insights into their processes, minimize downtime, and improve overall productivity.

Tips: To maximize the benefits of IoT integration, manufacturers should start by conducting a thorough assessment of their current machinery. Identifying areas where IoT can provide value, such as in energy consumption monitoring or equipment health checks, is crucial. Furthermore, investing in employee training for managing and interpreting IoT-generated data will ensure that teams can make informed decisions based on real-time insights.

Additionally, security should be a primary consideration when implementing IoT solutions. Manufacturers must ensure that their systems are protected from cyber threats, as increased connectivity can expose machines to vulnerabilities. Regular software updates and robust encryption methods are essential strategies to safeguard sensitive data and maintain the integrity of manufacturing processes.

Additive Manufacturing: Reducing Waste and Time with Innovative Techniques

Additive manufacturing, commonly known as 3D printing, is transforming the landscape of production efficiency by significantly reducing both waste and time. According to a report from McKinsey & Company, the adoption of additive manufacturing techniques can lead to a reduction in material waste by up to 90% when compared to traditional subtractive manufacturing methods. This remarkable decrease is primarily due to the layer-by-layer approach of additive processes, which uses only the necessary amount of material, minimizing excess scrap and maximizing resource use.

Moreover, a study by Deloitte estimates that companies utilizing additive manufacturing can reduce lead times by as much as 75%. This acceleration in production not only enables quicker turnaround times for prototypes but also facilitates faster manufacturing of end-use parts, thereby responding better to market demands. The ability to produce complex geometries that were previously impossible with conventional manufacturing techniques allows businesses to innovate and enhance their product offerings while keeping costs low. The integration of these innovative techniques is driving a paradigm shift in how industries approach manufacturing, underscoring the critical role of additive technologies in achieving greater efficiency and sustainability.

Top 10 Essential Manufacturing Machines Revolutionizing Production Efficiency

| Machine Type | Application | Efficiency Gains | Waste Reduction | Key Features |

|---|---|---|---|---|

| 3D Printer | Prototyping | Up to 50% faster than traditional methods | Minimizes material waste by up to 90% | Layered manufacturing, versatile materials |

| CNC Milling Machine | Metalworking | Increases precision and reduces cycle time | Reduces scrap by optimizing cutting paths | Automated controls, high-end tooling |

| Laser Cutter | Sheet metal cutting | Significant reduction in preparation time | Minimal kerf width reduces scrap | High precision, ability to cut complex shapes |

| Injection Molding Machine | Plastic part production | Increased production rate by 30% | Optimized material use minimizes waste | Fast cycle times, precision temperature control |

| Robotic Arm | Automated assembly | Boosts operational speed by 40% | Precision placement reduces part misalignment | Programmable, adaptable to various tasks |

| Wire EDM Machine | Precision machining | Enhances precision by 25% over traditional methods | Reduces scrap with tight tolerances | Electrical discharge machining, fine detail |

| Plasma Cutting Machine | Cutting thick materials | 30% faster than traditional cutting methods | Accurate cuts minimize waste | High temperatures, portable options |

| Vertical Turret Lathe | Large-scale part machining | Improves machining time by up to 40% | Efficient use of raw materials | Sturdy build, multiple tooling options |

| Multi-Spindle Machine | High-volume production | Increases throughput significantly | Minimizes tool changing time | Multiple spindles, synchronized operations |

| Heat Treatment Furnace | Material strengthening | Plans optimized for energy efficiency | Reduces excess use of energy and materials | Temperature control, programmable cycles |

Related Posts

-

Unlocking the Potential of Vibratory Polishing Machines: Tips for Optimal Performance and Maintenance

-

Top 10 Vibratory Polishing Machines for Perfect Finishing

-

How to Choose the Best Centrifugal Disc Finishing Machine for Your Needs

-

Why Automation Machines Are Essential for Modern Manufacturing Success

-

Mastering Finishing Systems: A Comprehensive Guide to Enhancing Product Quality and Performance

-

Top 10 UK Manufacturing Trends Transforming the Industry in 2023