2026 How to Choose the Right Manufacturing Machines for Your Business?

Choosing the right manufacturing machines for your business is a critical task. According to John Rivera, a leading expert in industrial automation, “The right machines can transform production efficiency.” This highlights the importance of making informed decisions.

When selecting manufacturing machines, consider your specific needs. Think about the scale of production and the types of products. It’s essential to research various machine options and compare their features. Yet, many businesses overlook key factors. They often focus on price alone, ignoring quality or efficiency.

Investing in high-quality manufacturing machines can lead to long-term benefits. However, it can be challenging to balance budget constraints with the desire for advanced technology. Sometimes, companies might make impulsive choices, leading to future regrets. It’s crucial to evaluate the overall impact of your selection, not just the immediate costs.

Understanding Your Manufacturing Needs and Goals

Understanding your manufacturing needs and goals is crucial when choosing the right machines. A 2022 report by the International Institute of Manufacturing highlights that 70% of manufacturing businesses struggle with machine integration. This statistic underscores the importance of aligning machine capabilities with business objectives.

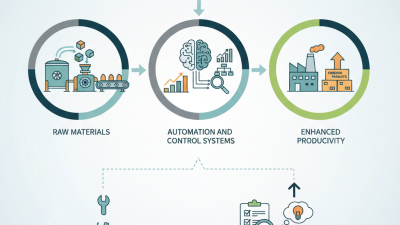

Consider the production volume and complexity. If your business aims for high-volume production, investing in automated machinery may be essential. Automated systems can enhance efficiency and reduce labor costs, but they require significant upfront investment. In contrast, companies focusing on custom, low-volume production might benefit from versatile machines that offer flexibility.

Assess the skill level of your workforce. A study by the National Institute of Standards and Technology shows that 60% of manufacturers face difficulties due to insufficient training. Machines with advanced technology may require specialized skills. Balancing advanced features with operator competency is often overlooked. Reflecting on these elements can lead to more informed decisions.

Evaluating Different Types of Manufacturing Machines

When selecting manufacturing machines, various types must be evaluated. Understanding the specific needs of your business is vital. Do you require automation or manual operation? Each type has its advantages and limitations. For instance, automated machines enhance efficiency but may require higher upfront investment. Manual machines are often less expensive but can slow down production.

Consider the materials you will work with. Some machines handle certain materials better than others. A CNC machine is excellent for precision cutting, while a 3D printer is ideal for prototypes. Reflect on your product lineup. Do you anticipate growth? Investing in scalable machines may be wise. However, if your production volume is low, it might be better to start with simpler machines.

Maintenance is another factor to ponder. Some machines need regular servicing and skilled personnel. This can add to your operational costs. Moreover, ensuring your team is trained can be a challenge. Don't overlook the potential disruption to your workflow during machine setup and training phases. Careful planning and evaluation of these considerations can lead to better decision-making.

Assessing Budget and Cost-Effectiveness of Machinery

When considering manufacturing machines, budget is a vital factor. You need to evaluate initial costs, maintenance, and operational expenses. A high upfront investment may seem appealing, but hidden costs can arise later. Analyze your cash flow to ensure that the machinery won't strain your finances.

Cost-effectiveness goes beyond price. Think about the lifespan and efficiency of the machines. Will they meet your production demands in the long run? It's essential to weigh these options carefully. Short-term savings may lead to higher expenses later. For instance, machines that consume more energy can hike up operational costs.

Investing in training for staff is crucial too. If workers cannot operate machines efficiently, productivity will suffer. Therefore, budget for training alongside the equipment purchase. Reflect on these factors, as overlooking them may lead to regrettable decisions in the future. Making a choice based solely on initial cost can compromise your overall success.

2026 How to Choose the Right Manufacturing Machines for Your Business? - Assessing Budget and Cost-Effectiveness of Machinery

| Machine Type | Initial Cost ($) | Operating Cost per Hour ($) | Maintenance Cost per Year ($) | Expected Lifespan (Years) | Production Capacity (Units/Hour) | Cost-Effectiveness Ratio |

|---|---|---|---|---|---|---|

| CNC Machine | $50,000 | $20 | $2,000 | 10 | 100 | 0.02 |

| Injection Molding Machine | $75,000 | $25 | $3,500 | 15 | 150 | 0.017 |

| Laser Cutting Machine | $60,000 | $15 | $1,800 | 12 | 120 | 0.013 |

Researching Suppliers and Machine Reliability

When selecting manufacturing machines, reliability is crucial. Researching suppliers thoroughly can save time and money. A report by the National Association of Manufacturers found that 56% of manufacturers cite supplier reliability as a key factor in their decision-making process. Machines that frequently break down can lead to production delays and increased costs.

Start your research by assessing supplier ratings. Look for data on machine performance and maintenance history. Websites like industry forums may offer insights into the experiences of other businesses. A KPI report noted that companies using reliable machinery tend to experience 30% less downtime. This is significant for maintaining productivity and profitability.

Tips: Compare warranty offers. A longer warranty can indicate manufacturer confidence in their machines. Also, consider local suppliers. They may provide quicker support and parts access. Balancing cost with quality is essential. A cheaper machine may not deliver the expected reliability, leading to hidden costs. Trust your instincts. If a supplier seems unresponsive, this could reflect their commitment to service. Investing time in research pays off with the right choice of equipment.

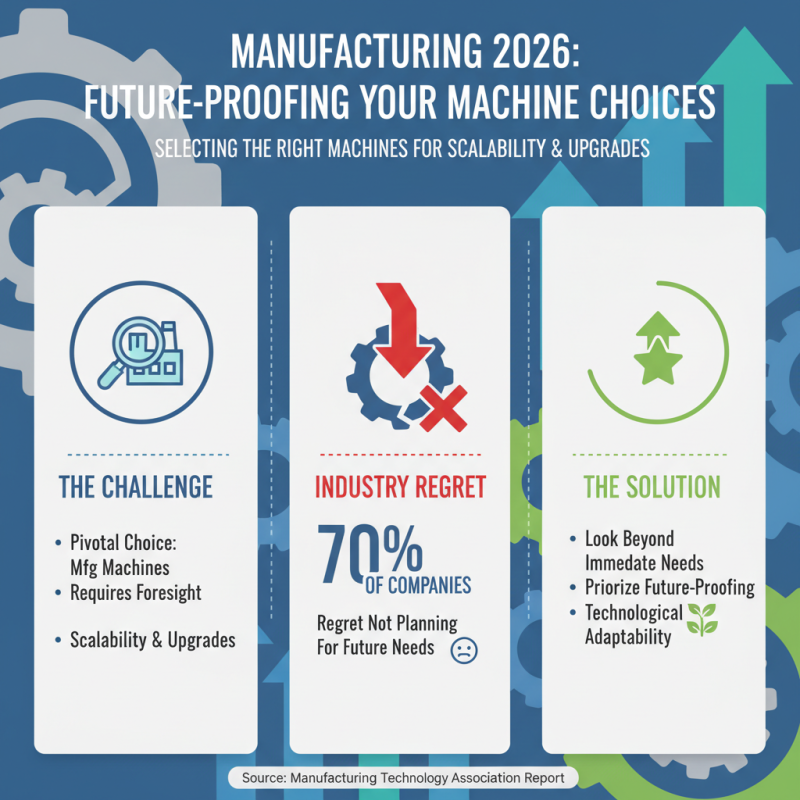

Considering Future Scalability and Technological Upgrades

In 2026, businesses face a pivotal challenge: selecting the right manufacturing machines. This choice requires foresight about future scalability and technological upgrades. According to a recent industry report by the Manufacturing Technology Association, 70% of companies regret not planning for future needs during equipment selection. This highlights the importance of looking beyond immediate requirements.

**Tip**: Assess your growth potential. Understanding the market landscape can guide your machine choices. For instance, if you anticipate a 20% increase in demand, select machines that can handle that growth efficiently.

Technological upgrades are crucial. The International Federation of Robotics states that automation can boost productivity by 30-50%. However, integrating new technologies isn't always seamless. Many companies struggle with outdated machines that hinder innovation. Regularly evaluating your equipment can prevent stagnation.

**Tip**: Consider maintenance capabilities. Machines that are hard to service can lead to downtime. Choose models that are user-friendly and have available support. This ensures that your business remains flexible and responsive to changes in the market.

Related Posts

-

Top 10 Manufacturing Machines You Need to Know for Your Business Growth

-

Top 10 Essential Manufacturing Machines Revolutionizing Production Efficiency

-

What is Manufacturing Machines and How They Revolutionize Production

-

Top 10 Manufacturing Machines That Revolutionize Production?

-

What is Process Machinery and How Does it Work?

-

Top 10 Process Machinery Types You Should Know for Your Business