How to Choose the Best Centrifugal Disc Finishing Machine for Your Needs

In the ever-evolving world of manufacturing, selecting the right machinery is crucial for optimizing production efficiency and quality. When it comes to surface finishing, the **centrifugal disc finishing machine** stands out as a versatile and effective solution. Industry expert Dr. Jane Smith, a leading engineer at Finishing Innovations, once remarked, "The right finishing machine can transform not only the quality of your products but also the efficiency of your processes." This underscores the importance of making an informed decision when choosing a centrifugal disc finishing machine tailored to your specific needs.

With various models and features available, understanding what to look for is essential for maximizing performance. Whether it’s for deburring, polishing, or cleaning, the right machine can make all the difference in achieving the desired results. Factors such as the materials being processed, the desired finish quality, and production volume all play critical roles in guiding the selection process. By considering these elements and leveraging expert advice, manufacturers can effectively navigate the complexities of choosing a suitable centrifugal disc finishing machine that meets their operational demands.

Understanding the Principles of Centrifugal Disc Finishing Machines

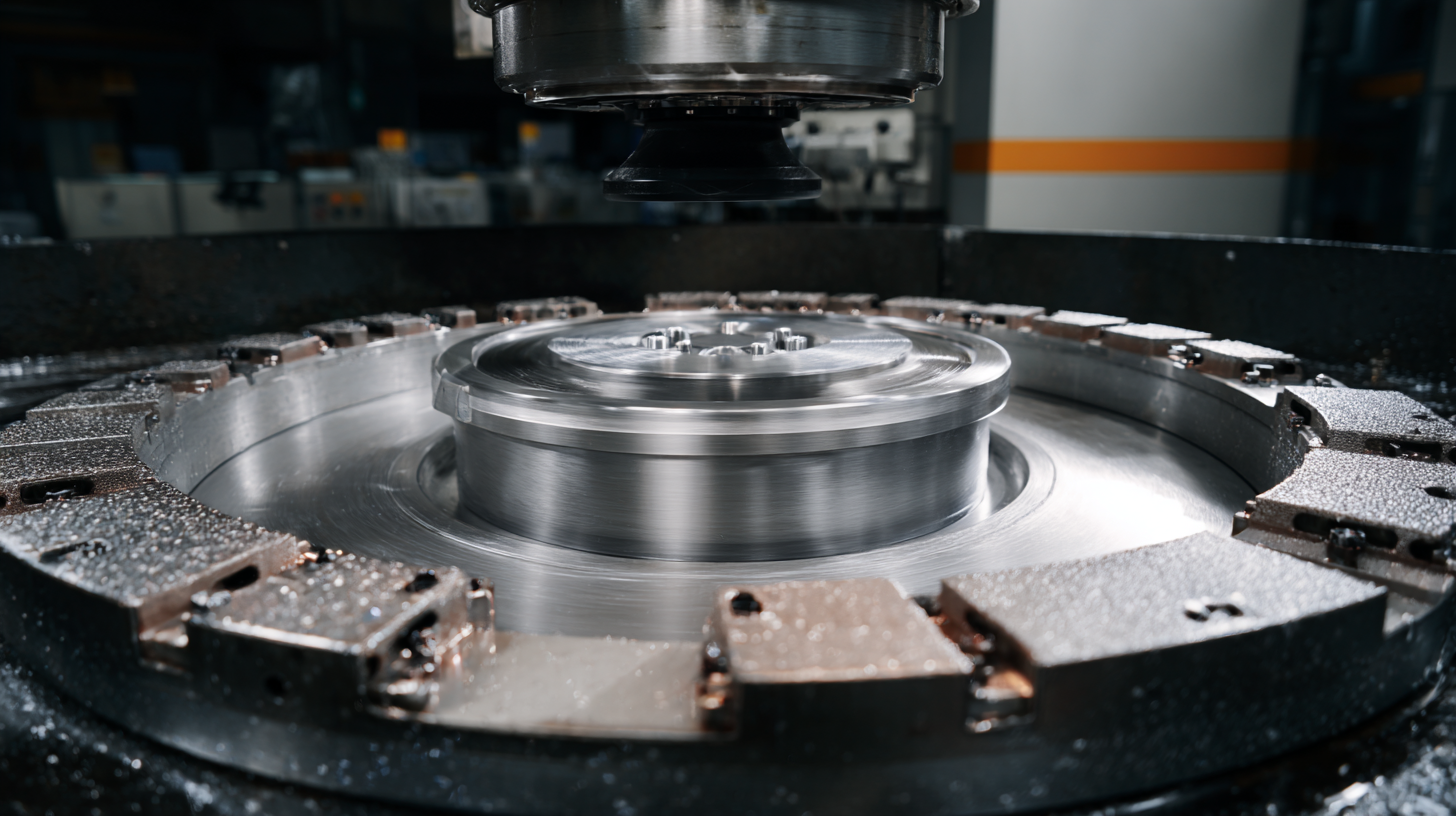

Centrifugal disc finishing machines operate on the principle of high-speed centrifugal forces that enhance the surface finishing process of various materials. By utilizing a rotating disc, these machines generate gravitational forces that propel workpieces against abrasive media, resulting in effective smoothing and polishing. According to industry reports, centrifugal disc finishing can increase processing efficiency by up to 60% compared to traditional methods, allowing companies to achieve tighter tolerances and superior surface finishes.

Centrifugal disc finishing machines operate on the principle of high-speed centrifugal forces that enhance the surface finishing process of various materials. By utilizing a rotating disc, these machines generate gravitational forces that propel workpieces against abrasive media, resulting in effective smoothing and polishing. According to industry reports, centrifugal disc finishing can increase processing efficiency by up to 60% compared to traditional methods, allowing companies to achieve tighter tolerances and superior surface finishes.

When selecting a centrifugal disc finishing machine, it's crucial to consider factors like the size of the workpieces, the type of materials being processed, and the desired finish quality. Tips for choosing the right machine include assessing your production volume needs and the specific types of media and compounds that align with your project requirements. Additionally, evaluating energy efficiency and maintenance costs can have long-term implications for operational effectiveness.

Incorporating advanced automation features can further enhance the performance of centrifugal disc finishing machines, as indicated by recent studies which show that automation can reduce labor costs by nearly 30%. This not only streamlines the process but also minimizes the risk of human errors, ensuring consistent and high-quality finishing results across production runs.

Identifying Your Specific Finishing Needs and Requirements

When selecting a centrifugal disc finishing machine, it’s crucial to first identify your specific finishing needs and requirements. Consider the materials you will be processing, the desired surface finish, and the shape of your components. Different machines are designed to handle various types of materials and finishing tasks, so understanding these factors will help narrow down your options.

**Tips:** Start by assessing the size and weight of the parts you work with. Ensure the machine you choose can accommodate these dimensions while providing the appropriate finishing action. Additionally, consider the throughput—how many parts you need to finish in a given time—which directly affects your productivity.

Another aspect to keep in mind is the type of media you will use for the finishing process. Choosing the right media can significantly impact the quality of the finish. Evaluate whether you require aggressive cutting, polishing, or deburring, and select a machine that offers versatility in media usage to match your evolving needs.

**Tips:** It's beneficial to request demonstrations or trial runs with different machines. This hands-on experience allows you to assess performance firsthand and ensures the machine aligns with your finishing requirements.

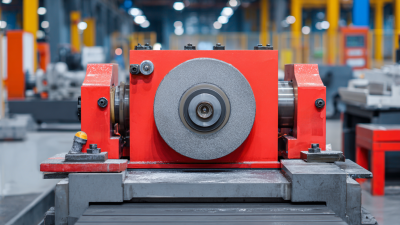

Evaluating Machine Features: Speed, Capacity, and Material Compatibility

When selecting a centrifugal disc finishing machine, understanding key features such as speed, capacity, and material compatibility is crucial to meet your specific finishing needs. Speed plays a significant role in determining the efficiency and effectiveness of the finishing process. According to a report by the International Journal of Advanced Manufacturing Technology, machines with a rotational speed between 300 and 600 RPM exhibit optimal performance for a variety of applications, significantly reducing processing times while maintaining surface quality.

Capacity is another essential factor to consider. The size of the bowl determines the quantity of workpieces that can be processed simultaneously. Industry data suggests that a larger capacity (up to 250 liters) can handle more substantial batches, improving throughput for high-volume operations. However, choosing a machine that balances capacity with your production scale is vital to avoid waste and inefficiencies.

Material compatibility is imperative for achieving desired outcomes without damaging components. For instance, a 2021 study indicated that machines capable of processing a diverse range of materials, from metal to plastic, are increasingly favored in the industry. Machines designed with adjustable parameters can accommodate different media types and shapes, ensuring versatility and effectiveness across various finishing tasks.

Budget Considerations and Long-Term Cost of Ownership

When selecting a centrifugal disc finishing machine, budget considerations play a crucial role in determining the best fit for your needs. The initial cost of the machine is often the most apparent expense, but understanding the long-term cost of ownership is equally important. This includes maintenance costs, energy consumption, and the potential need for additional accessories or upgrades. Investing in a higher-quality machine with better durability and efficiency may prove advantageous in the long run, as it can significantly reduce downtime and repair expenses.

Moreover, it’s essential to evaluate the operational efficiency of the machine. A more expensive model might feature advanced technology that enhances processing speeds and reduces finishing time, ultimately leading to increased productivity. Calculating the total cost of ownership, including how quickly the machine can pay for itself through operational savings, can help businesses make informed decisions.

Balancing upfront investment against long-term benefits will guide you toward a centrifuge that aligns with both your financial constraints and operational goals.

Choosing a Reliable Manufacturer and Reviewing Customer Feedback

When selecting a centrifugal disc finishing machine, one of the most critical factors is choosing a reliable manufacturer. According to a 2022 industry report by Market Research Future, the global market for surface finishing equipment is projected to grow at a CAGR of 5.8% over the next five years, indicating increasing competition and innovation among manufacturers. It’s essential to look for companies with a proven track record in the industry, ideally with certifications such as ISO 9001, which signifies adherence to quality management principles.

In addition to verifying manufacturer credentials, reviewing customer feedback can provide invaluable insights into a machine’s performance and durability. A study conducted by TechValidate found that 68% of manufacturers based their purchasing decisions on user reviews and testimonials. Engaging with existing customers or accessing platforms that compile reviews can reveal how machines perform under real-world conditions, potential maintenance issues, and overall satisfaction. This information can be instrumental in ensuring that you choose a machine that meets your specific needs and provides reliable service over its lifespan.

Related Posts

-

Top 10 UK Manufacturing Trends Transforming the Industry in 2023

-

Unlocking the Potential of Vibratory Polishing Machines: Tips for Optimal Performance and Maintenance

-

Why Automation Machines Are Essential for Modern Manufacturing Success

-

Top 10 Vibratory Polishing Machines for Perfect Finishing

-

Mastering Finishing Systems: A Comprehensive Guide to Enhancing Product Quality and Performance