How to Choose the Right Vibratory Polishing Machine for Your Needs

Choosing the right vibratory polishing machine can significantly impact the efficiency and quality of your polishing operations. With a variety of models available on the market, understanding the specific needs of your application is crucial in making an informed decision. Whether you're in manufacturing, jewelry design, or surface finishing, the right vibratory polishing machine can enhance productivity and consistency while ensuring that your components achieve the desired finish.

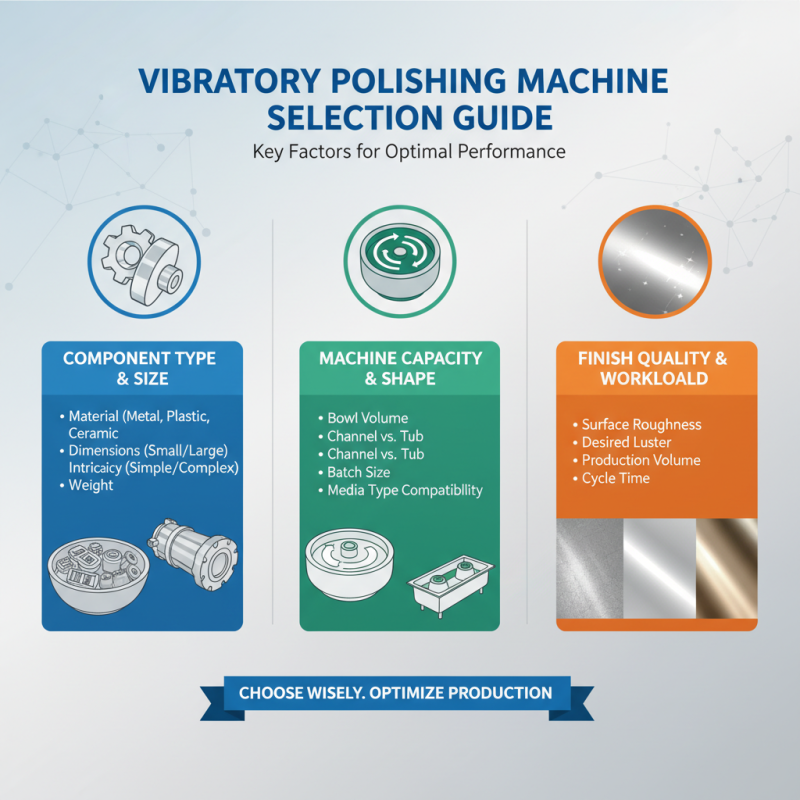

In selecting a vibratory polishing machine, it's essential to consider factors such as the size of the parts being polished, the type of materials involved, and the desired finish. Additionally, understanding the different features and capabilities of these machines can help you optimize your production process. From vibration frequency to bowl design, these elements can greatly influence the effectiveness of the polishing and the overall results you achieve.

Ultimately, investing in the correct vibratory polishing machine tailored to your needs will not only streamline your operations but also elevate the quality of your finished products. In this guide, we will explore key considerations that will help you navigate the selection process, ensuring that you choose a machine that aligns with your specific requirements and maximizes your polishing potential.

Understanding Vibratory Polishing Machines and Their Applications

Vibratory polishing machines are essential tools in various industries, providing an efficient method for finishing parts and components with precision and consistency. These machines utilize a combination of agitation and abrasive media to smooth surfaces, remove defects, and enhance the overall appearance of materials such as metals, plastics, and ceramics. By understanding their fundamental principles and applications, users can better assess how these machines can meet their specific needs.

In the realm of applications, vibratory polishing machines are widely employed in manufacturing environments, jewelry making, and even automotive industries. They are particularly beneficial for processing intricate shapes and delicate components, as the vibratory action allows for uniform contact and avoids damage that can occur with more aggressive finishing methods. Additionally, these machines can be tailored with various media types depending on the desired finish, whether it be a high-gloss shine or a matte surface. Recognizing the specific requirements of your projects is crucial in selecting the correct vibratory polishing machine that will yield optimal results while enhancing productivity.

Key Factors to Consider When Selecting a Vibratory Polishing Machine

When selecting a vibratory polishing machine, it’s essential to consider several key factors to ensure that it meets your specific requirements. First and foremost, assess the type and size of the components you plan to polish. Different machines offer varying bowl sizes and shapes, which impact the processing capacity and efficiency. A larger bowl may accommodate bulkier items but may not be practical for small, intricate parts. Conversely, smaller machines provide more precision for detailed work. Understanding your workload and the degree of surface finish required will help in choosing the right dimensions.

Another critical aspect to evaluate is the media and compound compatibility. Vibratory polishing machines utilize various media types, including ceramic, plastic, and metal, each affecting the final finish and processing time differently. Based on the materials you are polishing, it’s essential to choose a machine that can accommodate the appropriate media to achieve optimal results. Furthermore, consider the machine's adjustable features, such as vibration intensity and time settings, as these settings can greatly influence the polishing process's effectiveness. By focusing on these factors, you can make an informed decision and select a vibratory polishing machine that aligns perfectly with your needs.

Different Types of Vibratory Polishing Machines Available on the Market

When selecting a vibratory polishing machine, it’s essential to understand the different types available to meet your specific needs. Vibratory polishing machines generally fall into several categories, including batch-type, continuous-feed, and high-energy models. Batch-type machines are ideal for small to medium-sized operations where polishing is done in discrete batches. They offer flexibility in processing different materials and can achieve a variety of finishes, making them popular for workshops that handle diverse workloads.

On the other hand, continuous-feed machines are designed for larger operations requiring constant throughput. These machines allow for uninterrupted processing, which is efficient for high-volume polishing tasks. They are well-suited for mass production scenarios and can handle larger components with ease. High-energy vibratory polishing machines are another option, offering faster processing times and enhanced finishing capabilities. These are perfect for applications that demand short cycle times and superior surface finishes, such as in the automotive or aerospace industries. By understanding the distinctions between these types of machines, you can make an informed decision that aligns with your operational requirements.

Types of Vibratory Polishing Machines and Their Applications

Evaluating the Size and Capacity of Your Polishing Machine Needs

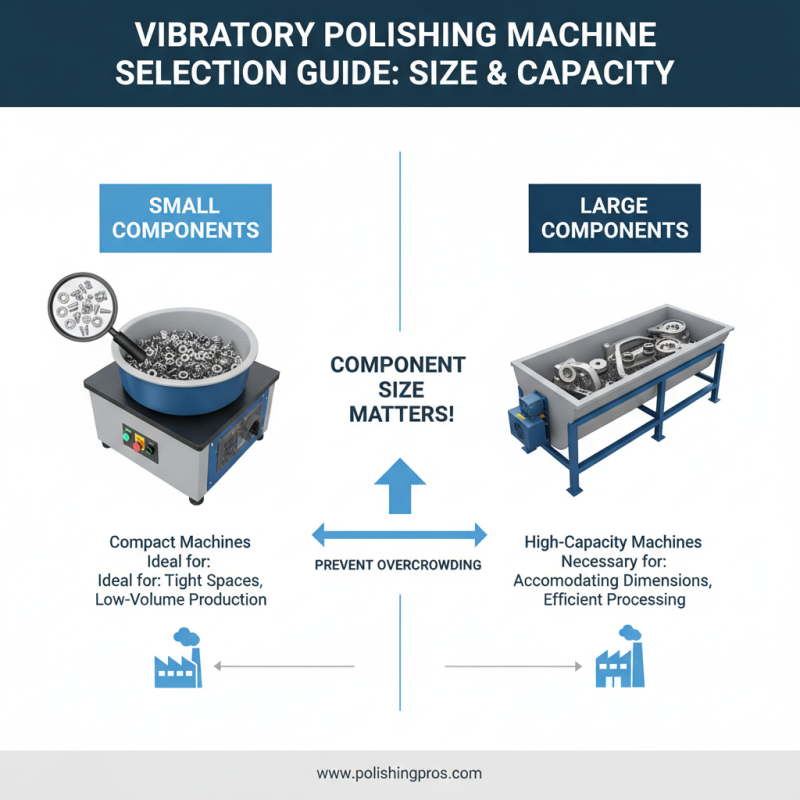

When selecting a vibratory polishing machine, understanding the size and capacity that meets your specific needs is crucial. The first consideration should be the size of the components you intend to polish. Smaller parts can often be processed in compact vibratory machines, which are ideal for tight spaces and lower volume production. On the other hand, if you work with larger components, a machine with a greater capacity will be necessary to accommodate the dimensions and allow for more efficient processing without overcrowding.

Additionally, the capacity of the machine, often determined by the volume of media and parts it can handle at one time, must align with your production expectations. Assess how much material you need to polish within a specific timeframe. If your demands are high, investing in a larger machine that can process more parts simultaneously will improve your workflow and productivity. However, balance is key; selecting a machine excessively larger than your needs may lead to inefficient operation and higher energy costs. Ultimately, understanding your specific requirements regarding size and capacity will lead to a more effective choice in your vibratory polishing machine selection.

Budget Considerations and Long-Term Investment in Polishing Equipment

When choosing a vibratory polishing machine, understanding budget considerations and long-term investment potential is crucial. While it may be tempting to opt for the cheapest models available, investing in quality equipment can save you significant costs over time. Higher-quality machines typically offer better durability, efficiency, and effectiveness, which can lead to reduced maintenance costs and increased productivity for your polishing tasks.

Tips for budgeting wisely include assessing not only the initial purchase price but also any ongoing operational costs. Consider factors such as energy consumption, maintenance requirements, and the expected lifespan of the equipment. By factoring in these elements, you’ll be better equipped to gauge the true cost of ownership and choose a machine that offers long-term value, rather than just a lower upfront cost.

Additionally, it’s beneficial to look into the resale value of the polishing equipment. High-quality machines tend to retain their value better than cheaper alternatives; thus, should you ever decide to upgrade, your initial investment could translate into a better return. Evaluating the long-term benefits of your vibratory polishing machine can make a significant difference in your overall operational efficiency and financial sustainability.

Related Posts

-

Why You Should Invest in a Vibratory Polishing Machine for Your Business

-

Unlocking the Potential of Vibratory Polishing Machines: Tips for Optimal Performance and Maintenance

-

Top 10 Vibratory Polishing Machines for Perfect Finishing

-

How to Choose the Best Centrifugal Disc Finishing Machine for Your Needs

-

Top 10 Essential Manufacturing Machines Revolutionizing Production Efficiency

-

Top 10 Benefits of Using Vibro Machines for Effective Workouts