Top 10 Best Finishing Machines for Quality Print Finishing in 2023

In the ever-evolving landscape of print production, the significance of a high-quality finishing machine cannot be overstated. As we delve into 2023, industry expert John Smith, a renowned figure in print technology, emphasizes, "The right finishing machine not only enhances the aesthetic appeal of printed materials but also plays a crucial role in streamlining production workflows." This statement underscores the pivotal role that finishing machines play in delivering superior print outcomes.

As businesses strive for excellence, selecting the best finishing machine has become a vital consideration for printers dedicated to achieving top-tier results. From cutting and binding to laminating and embossing, these machines offer an array of functionalities that can elevate the quality of printed products. In this article, we explore the top 10 finishing machines that stand out in 2023, highlighting their features, benefits, and the transformative impact they have on the print finishing process. Discover how investing in the right finishing machine can revolutionize your printing capabilities and ensure your work stands out in a competitive market.

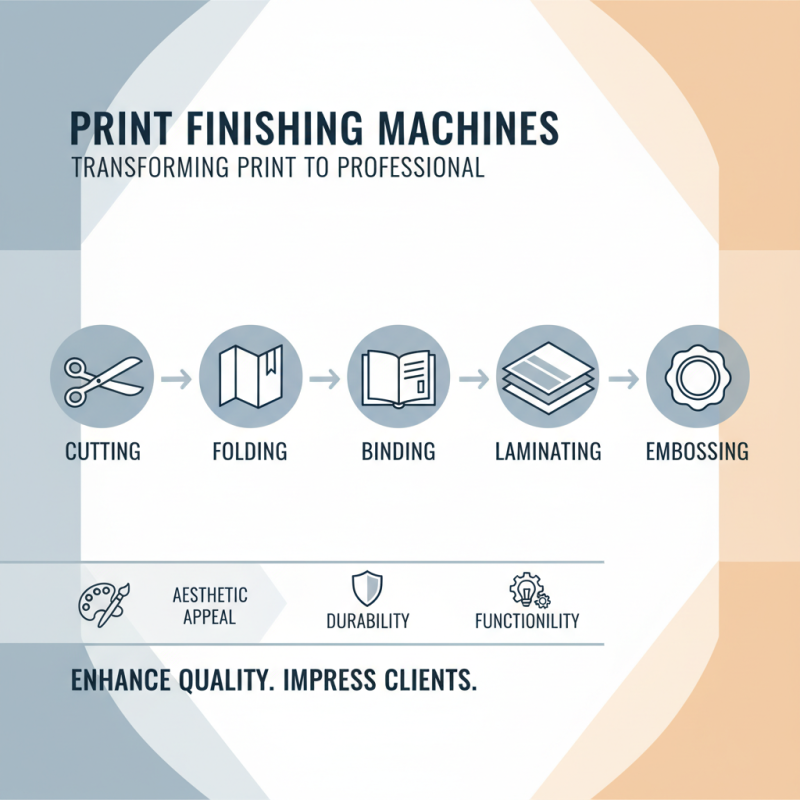

Overview of Print Finishing Machines and Their Importance

Print finishing machines play a crucial role in the printing industry, transforming raw printed materials into polished, professional products. These machines encompass a wide range of processes, including cutting, folding, binding, laminating, and embossing. By adding these finishing touches, they enhance the aesthetic appeal, durability, and functionality of printed materials. Proper finishing not only improves the overall quality of printed products but also helps in creating a lasting impression on clients and consumers.

In an era where visual presentation is paramount, the importance of high-quality print finishing cannot be overstated. It ensures that printed items, whether they are business cards, brochures, or packaging, maintain their design integrity and stand out in a competitive market. With advancements in technology, modern finishing machines offer greater precision and efficiency, allowing print service providers to meet high demand while still producing exceptional results. As businesses strive to deliver superior quality, investing in reliable print finishing machinery becomes an essential step for maintaining competitiveness and satisfying customer expectations.

Key Features to Consider When Choosing Finishing Machines

When selecting a finishing machine for quality print finishing, several key features should be considered to ensure optimal performance and integration into your existing workflow. One essential factor is the machine's versatility in handling various substrates, as the ability to process different media types expands the potential applications for your print work. A report by Smithers Pira indicates that the demand for varied finishing techniques is surging, reflecting a 4% annual growth in this segment. Thus, a machine that accommodates paper, cardstock, and synthetic materials can provide greater flexibility in meeting diverse client needs.

Another important aspect is automation capabilities. Advanced finishing machines equipped with automated settings can significantly enhance productivity and reduce labor costs. According to Research and Markets, automated finishing options are projected to account for over 60% of market growth in the coming years. This automation not only streamlines operations but also minimizes the risk of human error, which is critical in maintaining quality standards in high-volume production environments.

Tips: When evaluating finishing machines, inspect the ease of user interface and software integration. Machines that offer intuitive controls and seamless compatibility with design software can greatly reduce training time and enhance operational efficiency. Additionally, consider the machine's maintenance requirements; easier maintenance schedules can lead to increased uptime and reduced long-term operational costs. Finally, be sure to assess energy efficiency, as machines that consume less energy contribute to both cost savings and environmental sustainability.

Top 10 Finishing Machines for Quality Print Finishing in 2023

In 2023, the print finishing industry continues to evolve, driven by technological advancements and the increasing demand for high-quality output. To meet these needs, selecting the right finishing machine is crucial for businesses aiming to enhance their production efficiency and print quality. According to a recent industry report by Smithers Pira, the global print finishing market is projected to reach $7.4 billion by 2025, indicating a robust growth trajectory that highlights the significance of investing in top-notch finishing equipment.

When choosing a finishing machine, consider factors such as speed, versatility, and ease of operation. Many modern machines now offer capabilities such as automated setup, which minimizes downtime and boosts productivity. Additionally, machines that handle multiple finishing techniques—like laminating, binding, and cutting—can significantly streamline workflows. It’s essential to focus on models equipped with advanced features like digital controls and adaptive technology to meet varying job specifications while maintaining high quality.

**Tips:** Always evaluate your production needs before selecting a machine. Understanding the volume and types of jobs you’ll be processing can help you choose a finishing machine that matches your operations. Also, consider the long-term costs of ownership, including maintenance and operational expenses, to ensure a sound investment decision. Finally, seeking machines that offer training and reliable customer support can enhance your team's efficiency and confidence in utilizing complex systems.

Top 10 Best Finishing Machines for Quality Print Finishing in 2023

Detailed Reviews of Each Recommended Finishing Machine

In 2023, the landscape of print finishing has evolved significantly, focusing on efficiency, quality, and automation. As businesses strive for superior print solutions, selecting the right finishing machine is crucial. Advanced models now offer features like precision cutting, high-speed laminating, and digital binding, all tailored to meet the growing demands of both small and large print jobs. According to industry reports, there's been a 15% increase in demand for automated finishing solutions, emphasizing the necessity for machines that enhance workflow and minimize human error.

When considering a finishing machine, it’s essential to evaluate the specific needs of your print operations. Look for machines that provide versatility in handling different materials and sizes, as well as those that incorporate user-friendly interfaces for easy operation. Additionally, machines with the ability to integrate seamlessly into existing workflows can save time and reduce the learning curve for operators.

Tip: Always assess the total cost of ownership, including maintenance and operational costs, to ensure you select a machine that not only fits your budget but also offers long-term value. Keeping an eye on emerging technologies in print finishing can also give your business a competitive edge by ensuring you are equipped with the latest tools and capabilities.

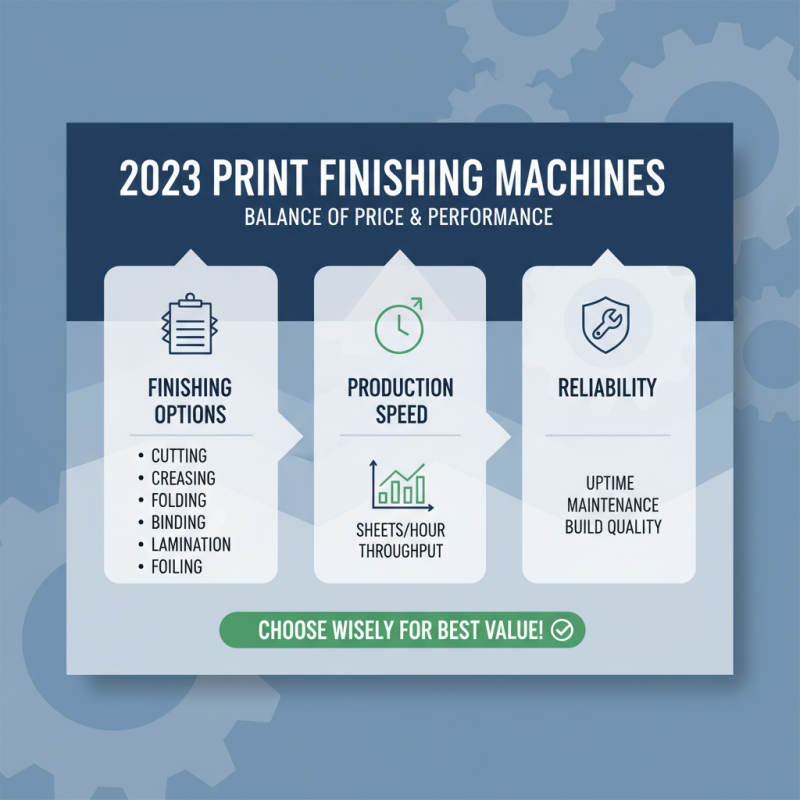

Comparison of Pricing and Performance of Top Finishing Machines

When it comes to print finishing, the right machine can significantly impact the final quality of your work. In 2023, a variety of finishing machines are available that balance pricing and performance, making it crucial for businesses to choose wisely. Key factors to consider include the types of finishing options the machine offers, its production speed, and overall reliability. A thorough comparison of these machines will help identify which models provide the best value for your investment.

Tips for selecting a finishing machine include assessing your specific needs according to your work volume and the types of projects you handle. If high-volume production is a priority, consider machines known for their efficiency and durability. Additionally, researching user reviews can provide insights into real-world performance and longevity. It’s also beneficial to analyze the total cost of ownership, including maintenance expenses, to ensure that your chosen machine remains a smart long-term investment.

Another crucial aspect is understanding the technological advancements incorporated in modern finishing machines. Features such as automation and user-friendly interfaces can greatly enhance productivity. When comparing machines, look for those that offer versatile functionalities, allowing you to adapt your finishing process to various types of print jobs. This flexibility can set your work apart and satisfy a wider clientele.

Related Posts

-

Mastering Finishing Systems: A Comprehensive Guide to Enhancing Product Quality and Performance

-

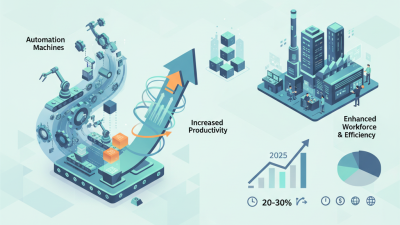

How to Use Automation Machines to Enhance Productivity in 2025

-

How to Choose the Right Vibratory Polishing Machine for Your Needs

-

Top 10 Vibratory Polishing Machines for Perfect Finishing

-

Why Automation Machines Are Essential for Modern Manufacturing Success

-

Top 10 UK Manufacturing Trends Transforming the Industry in 2023