What is an Automation Machine? Understanding Its Types and Applications

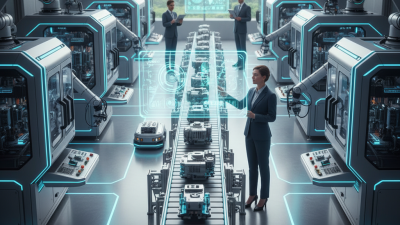

In an era marked by rapid technological advancements, the role of automation machines has become increasingly pivotal in enhancing operational efficiency across various industries. An automation machine refers to equipment or systems that perform tasks with minimal human intervention, leveraging technologies such as robotics, artificial intelligence, and integrated software to drive productivity. As businesses seek to streamline operations, reduce costs, and improve consistency in output, understanding the different types of automation machines and their applications becomes essential.

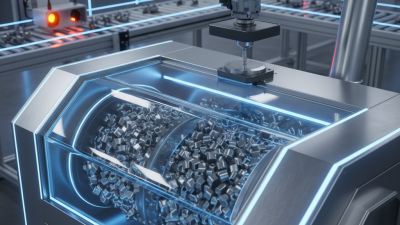

There are several categories of automation machines, each serving unique functions tailored to specific industry needs. From robotic arms in manufacturing to automated guided vehicles in warehousing, these machines have revolutionized traditional processes by enabling faster, safer, and more precise operations. Furthermore, the application of automation machines extends beyond manufacturing and logistics to sectors such as healthcare, agriculture, and finance, where they simplify complex tasks and contribute to better quality outcomes.

As we delve deeper into the world of automation machines, it becomes clear that their impact is profound and multifaceted. With the continued evolution of technology, automation machines hold the potential to shape the future of work, making it crucial for businesses to adapt and integrate these systems into their operations for sustainable growth and competitive advantage.

What is an Automation Machine?

An automation machine refers to any device or system designed to perform a specific task with minimal human intervention. These machines leverage technology to enhance efficiency, accuracy, and productivity across various industries. Whether in manufacturing, packaging, or quality control, automation machines have become integral in streamlining processes and reducing operational costs. They facilitate the automation of repetitive tasks, allowing human workers to focus on more complex, strategic activities.

There are several types of automation machines, each tailored to specific applications. For instance, robotic arms are commonly employed in assembly lines for tasks like welding or material handling. Conveyor systems transport goods seamlessly through production facilities, while automated guided vehicles (AGVs) manage the movement of materials within warehouses. Additionally, programmable logic controllers (PLCs) serve as the brain of many automation systems, enabling real-time control and monitoring of processes. The versatility and adaptability of these machines make them essential in modern industrial operations, driving advancements in technology and productivity.

Key Components of Automation Machines

Automation machines are integral to modern manufacturing and industry, designed to perform tasks with minimal human intervention. A key aspect that underpins their functionality lies in the various components that make up these systems. Understanding these components is crucial for optimizing performance and efficiency.

At the core of automation machines are sensors, which collect data about the environment or operational status. These sensors can detect various parameters such as temperature, pressure, and motion, providing real-time feedback that allows the machine to adjust its actions accordingly. Another essential component is the actuator, which executes mechanical movements based on signals received from a control system. Actuators convert energy into physical motion, enabling tasks such as assembly, welding, and material handling.

Additionally, the control system is a vital element in automation machines, typically comprising software and hardware that processes data from sensors and directs actuators. This system ensures that tasks are conducted in a coordinated manner, following predefined protocols. The integration of these components creates a seamless operation, enabling automation machines to perform consistently and reliably across various applications, from automotive assembly lines to pharmaceutical production.

Types of Automation Machines and Their Functions

Automation machines play a crucial role in modern manufacturing and production processes, providing increased efficiency and reduced labor costs. There are several types of automation machines, each tailored to specific tasks and industry requirements. For instance, industrial robots are widely used for tasks such as welding, painting, and assembly. According to a report by the International Federation of Robotics, the global market for industrial robots is projected to reach $209 billion by 2024, driven by advancements in AI and machine learning technologies.

Another significant category is programmable logic controllers (PLCs), which are essential for controlling machinery and processes. PLCs provide flexibility in automation systems, allowing for easy reprogramming to accommodate changing production needs. The Automation Federation reports that the demand for PLCs has surged as more companies adopt automation solutions, with the market expected to grow at a compound annual growth rate (CAGR) of 5.6% through 2028. Additionally, machine vision systems are gaining traction for their ability to inspect and identify products with precision, significantly reducing error rates in production lines.

Each type of automation machine contributes uniquely to enhancing productivity and quality, addressing the specific demands of industries such as automotive, consumer goods, and electronics. As organizations continue to seek ways to optimize their operations, the integration of advanced automation technologies remains a key driver of growth and innovation.

Industries Utilizing Automation Machines

Automation machines have become increasingly integral across various industries, streamlining processes and enhancing efficiency. One of the primary sectors leveraging these technologies is manufacturing. In manufacturing, automation machines facilitate repetitive tasks such as assembly, welding, and painting, resulting in reduced labor costs and improved precision. Advanced robotics and conveyor systems are examples of automation machines that enable a smoother workflow and faster production rates, ultimately leading to higher output and quality control.

Another significant industry utilizing automation machines is logistics and warehousing. Here, automation technologies such as automated guided vehicles (AGVs) and robotic arms optimize warehouse management by automating the movement of goods and inventory management. By leveraging these machines, companies can significantly decrease the time spent on order fulfillment and improve accuracy in stock handling. Moreover, the integration of automation in this sector helps in managing high volumes of orders efficiently, particularly during peak times, contributing to overall operational effectiveness.

Future Trends in Automation Machine Technology

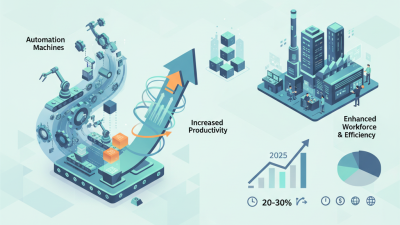

The landscape of automation machine technology is rapidly evolving, influenced by advancements in artificial intelligence, machine learning, and the Internet of Things (IoT). As industries strive for greater efficiency, automation machines are becoming smarter and more adaptable, allowing for seamless integration into various processes. Future trends indicate a shift towards collaborative robots (cobots) that work alongside humans, enhancing productivity while maintaining safety. Moreover, predictive maintenance powered by data analytics will enable businesses to minimize downtime and reduce operational costs.

Tips: When considering the adoption of automation machines, conduct a thorough analysis of your workflow to identify areas where automation can add the most value. Additionally, invest in training programs for your workforce to ensure they are equipped to work alongside these advanced technologies.

Another significant trend is the rise of hyper-automation, which leverages advanced technologies to automate complex business processes. This approach not only improves efficiency but also enhances decision-making through real-time data insights. As organizations embrace this comprehensive automation strategy, they can expect increased productivity and a competitive edge in the market.

Tips: Start small by implementing automation in specific tasks before scaling up. This gradual approach allows you to evaluate the effectiveness of technology investments and make necessary adjustments to maximize return on investment.

Related Posts

-

How to Use Automation Machines to Enhance Productivity in 2025

-

Top 10 Benefits of Using Automation Machines for Your Business Efficiency

-

Top 10 Essential Manufacturing Machines Revolutionizing Production Efficiency

-

2025 Top Vibratory Finishing Machine Trends and Best Options

-

Top 10 Manufacturing Machines You Need to Know for Your Business Growth

-

Mastering Finishing Systems: A Comprehensive Guide to Enhancing Product Quality and Performance