2025 Top Vibratory Finishing Machine Trends and Best Options

The vibratory finishing machine market is poised for significant growth, driven by advancements in technology and increasing demand for efficient surface finishing processes across various industries. According to a recent market research report by MarketWatch, the global vibratory finishing machine market is projected to reach USD 1.6 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.4% from 2020 to 2025. This growth is largely attributed to the rising emphasis on quality and aesthetics in products, along with the need for process automation and cost reduction in manufacturing.

As industries such as automotive, aerospace, and jewelry increasingly seek cost-effective and high-quality finishing solutions, the vibratory finishing machine has become a critical component of production lines. With the advancements in machine design and technology, including greater energy efficiency and automation features, businesses are now better equipped to enhance productivity and meet stringent quality standards. Furthermore, innovation in materials and processes will pave the way for new applications, making vibratory finishing machines a vital investment for manufacturers aiming to stay competitive in the rapidly evolving market landscape.

In this context, understanding the latest trends and best options for vibratory finishing machines is crucial for industry stakeholders. From emerging technologies to evolving customer preferences, this article will delve into the key developments shaping the vibratory finishing machine market and highlight the best options available for businesses to consider in their quest for enhanced efficiency and product quality.

Emerging Technologies in Vibratory Finishing Machines for 2025

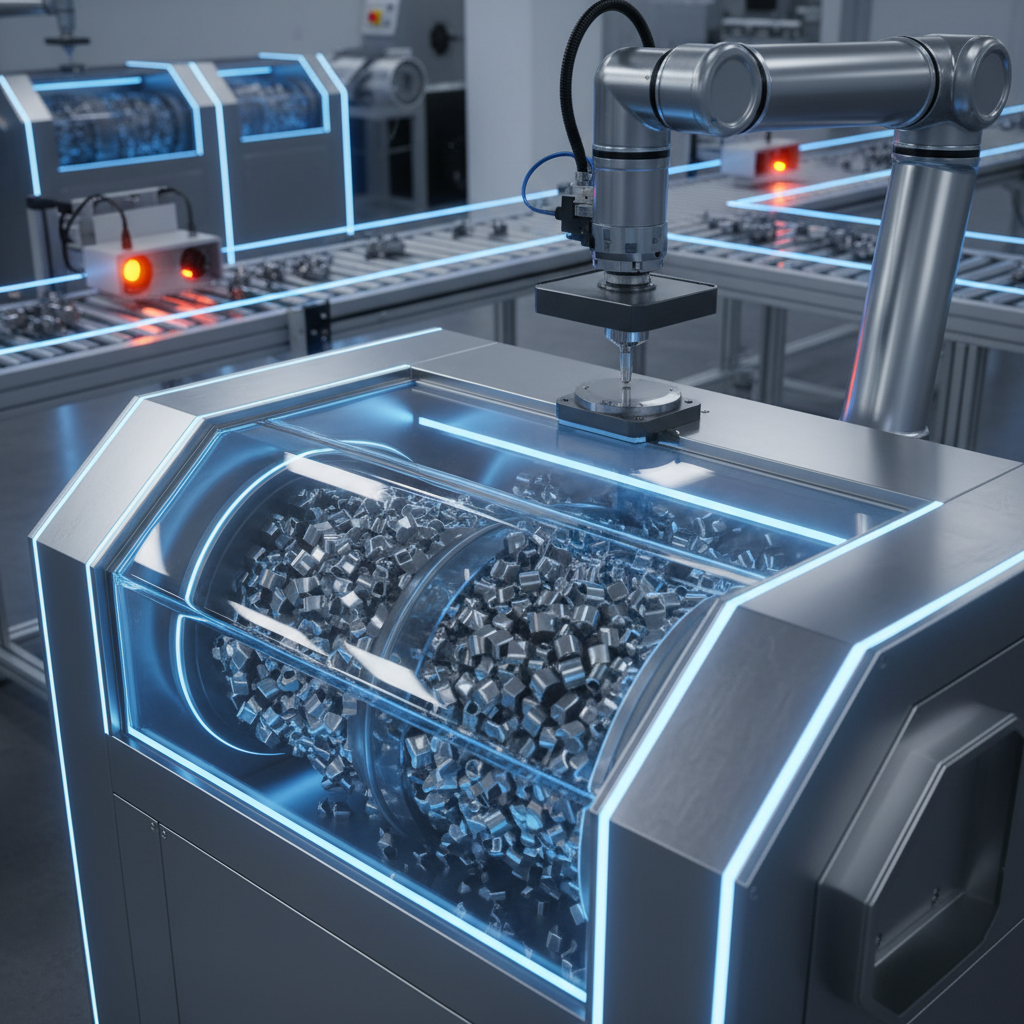

As we look towards 2025, the vibratory finishing machine industry is poised to undergo significant transformation driven by emerging technologies. One of the most notable trends is the integration of automation and artificial intelligence into the finishing process. These innovations enable machines to adjust their parameters in real-time based on the characteristics of the materials being processed, resulting in enhanced efficiency and consistency in surface finishing.

Additionally, advancements in sensor technology are set to play a crucial role in the vibratory finishing landscape. With improved sensors, machines will be capable of monitoring various operational metrics, such as vibration frequency and amplitude, which can lead to predictive maintenance and reduced downtime. Moreover, smart connectivity options, including IoT integration, will allow for remote monitoring and control, enabling operators to oversee multiple machines simultaneously and optimize performance without being physically present. These emerging technologies not only promise to enhance productivity but also to deliver higher quality finishes, setting a new standard for vibratory finishing in 2025.

Key Features to Look for in Top Vibratory Finishing Machines

When selecting a vibratory finishing machine, understanding key features is essential for ensuring optimal performance and durability. One critical aspect to consider is the machine's capacity and size, which should be aligned with the volume of parts you plan to process. According to industry reports, machines with a capacity range of 4 to 12 cubic feet are the most popular among manufacturers, striking a balance between efficiency and space-saving design. Additionally, the material composition of the machine plays a vital role in its longevity; stainless steel components are preferred due to their resistance to corrosion and wear.

Another significant feature to look for is the machine's vibration intensity and adjustability. High-quality vibratory machines allow users to modify the vibration frequency and amplitude, which can enhance the finishing results and accommodate different materials. Industry research has shown that machines with adjustable settings can improve processing times by up to 30%, making them a valuable investment for any finishing operation.

Tips: Prioritize machines that offer energy-efficient motors, as they not only reduce operational costs but also improve the machine's overall sustainability. Furthermore, consider investing in models equipped with digital controls for greater precision in managing the finishing process. This attention to detail can significantly enhance your production's quality and efficiency.

Comparative Analysis of Leading Brands in Vibratory Finishing Equipment

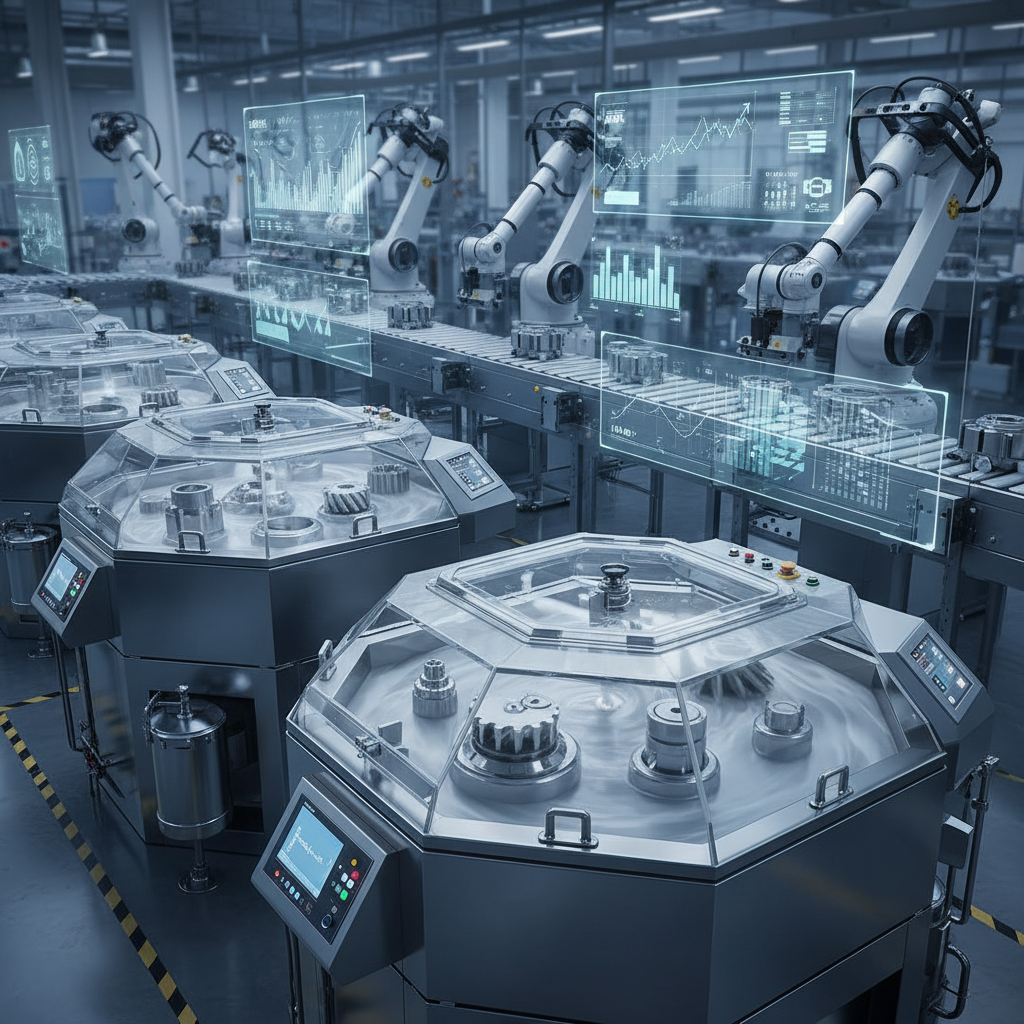

The vibratory finishing machine market is witnessing significant changes as advancements in technology and increased demand for efficient finishing processes drive innovation. Leading manufacturers are focusing on optimizing their machines for better performance, enhanced durability, and user-friendly operation. This comparative analysis highlights the current trend towards integrating smart technologies into vibratory finishing equipment, which includes features such as automated control systems and data analytics capabilities, enabling users to monitor and optimize their finishing processes in real-time.

Notably, the competitive landscape of the vibratory finishing equipment market is characterized by a mix of established players and emerging brands. The analysis indicates that brands are focusing on increasing their market share through strategic collaborations and product innovations. As sustainability becomes a priority across industries, many companies are also enhancing their offerings to include eco-friendly materials and energy-efficient systems. This evolution in the vibratory finishing machine segment promises to provide users with a broader range of options tailored to their specific needs, making it essential for manufacturers to stay ahead in this dynamically evolving market.

Sustainability Trends Influencing the Vibratory Finishing Industry

The vibratory finishing industry is increasingly influenced by sustainability trends that shape its operational and strategic frameworks. As companies strive to reduce their environmental footprint, there is a notable shift towards the adoption of eco-friendly materials and processes. These trends include the use of biodegradable compounds and energy-efficient machinery that not only support sustainable practices but also enhance product quality and manufacturing efficiency.

In response to growing regulatory pressures and consumer demand for greener solutions, many manufacturers are innovating their product lines. The integration of advanced technologies, such as vibration damping materials, plays a crucial role in minimizing waste and energy consumption. Furthermore, by leveraging machine learning and vibrational spectroscopy, businesses can optimize their production processes, ensuring that sustainability and efficiency go hand-in-hand. This evolution in the vibratory finishing sector reflects a broader commitment to environmental stewardship and a forward-thinking approach to industrial practices.

Future Market Predictions for Vibratory Finishing Machines in 2025

The vibratory finishing machine market is expected to experience significant growth by 2025, driven by advancements in technology and increasing demand across various industries. According to a recent market research report by QY Research, the global vibratory finishing machine market size was valued at approximately $1.1 billion in 2020 and is projected to reach $1.6 billion by 2025, growing at a compound annual growth rate (CAGR) of 7.5%. This growth is largely attributed to heightened automation in manufacturing processes and the rising importance of surface finishing in enhancing product quality.

As industries continue to embrace innovation, the trend of eco-friendly and sustainable finishing solutions is gaining momentum. Reports indicate that manufacturers are increasingly looking for vibratory finishing machines that minimize energy consumption and use biodegradable media. For example, the 2022 Global Surface Treatment Market Analysis highlights a shift towards machines that incorporate smart technology for energy efficiency, which not only reduces operational costs but also meets the growing regulatory standards for environmental sustainability. By leveraging smart sensors and IoT capabilities, these modern machines are set to redefine efficiency and effectiveness in vibratory finishing applications.

Related Posts

-

Why You Should Choose Dalal Vibro Finishing Machine for Superior Surface Finishing

-

Top 10 Vibratory Polishing Machines for Perfect Finishing

-

Unlocking the Potential of Vibratory Polishing Machines: Tips for Optimal Performance and Maintenance

-

Top 10 UK Manufacturing Trends Transforming the Industry in 2023

-

How to Choose the Best Centrifugal Disc Finishing Machine for Your Needs

-

What is Manufacturing Machines and How They Revolutionize Production